What’s new? 17 new standard configurations. The blenders also are customizable.

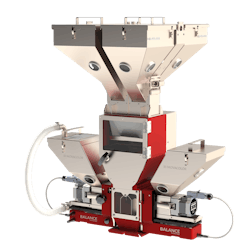

Benefits Accuracy of within 0.02 percent. By adding a dosing unit, users can more carefully dose higher-cost materials, reducing waste and lowering expenses. According to Movacolor, the blenders have a compact and sturdy design, with no mechanical and/or moving parts in the hoppers. Standard versions of the blenders carry lead times of only seven weeks.

Movacolor, 262-675-3035, [email protected], www.movacolor.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.