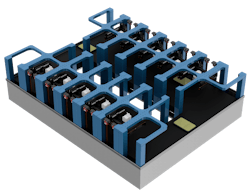

Matrix6D Advanced Printed Electronic Solutions (APES) has launched this modular, multi-tool-station additive manufacturing (AM) system as an option for manufacturers looking to scale up AM production from prototyping to large volumes. Featuring a toolhead module and grid-based, tool-cell architecture that can accommodate any number of tool stations, the Matrix6D can accommodate varying toolhead sizes, tool station densities and build volumes. Every Matrix6D is a mini manufacturing unit that can perform any combination of material deposition — including aerosol jet, inkjet, direct write, dispensing or extrusion — as well as non-additive processes, including curing/post-processing, pick-and-place robots or other tools, such as vision systems for calibration and inspection. The design allows multiple manufacturing recipes to run in parallel, making it ideal for semiconductor and electronic device packaging, additively fabricated circuit boards, metamaterial optics and other applications.

What’s new? The Matrix6D, which was announced in April with the integration of a cone-beam volumetric printing process from APES partner Manifest Technologies, Boulder, Colo. The process uses a single cone of light and XY rastering to solidify entire 3D objects without layers, supports or rotation.

Benefits Scalability and flexibility, with the ability to make different parts on the same platform at once. The Matrix6D gives users the ability to bring together multiple tools of the same or different types, and parts can progress from station to station. Among other applications, it could be used for overprinting metal components and embedding electronics within complex geometries — use cases that have been largely out of reach for traditional photopolymer systems.

Advanced Printed Electronic Solutions, Fishkill, N.Y., https://advpes.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.