By Karen Hanna

Over years that saw shortages of everything from toilet paper to medical supplies, manufacturers demonstrated 3D printer technologies’ capacity to help users localize production and quickly adapt to challenges in the market.

Additive manufacturing (AM) technology — used in the worst days of the pandemic to make essential items including nasal swabs and personal protective equipment — still has potential to buttress the supply chain, experts say.

“Everything that happened in the last three years around the supply chain disruption, whether it’s COVID, whether it’s ships getting stuck in the Suez Canal, or whether it’s now geopolitical tensions that are creating concerns around supply chain assurance, I think all of these have stressed the need for a more agile production method, or even production alternatives, such as 3D printing,” said Tali Rosman, an AM expert who advises early-stage companies on strategy, product roadmap and corporate development.

Related: 3D printing OEMs are scaling up

As the acute crises of the COVID-19 pandemic and resulting supply chain snags recede, AM technologies continue to offer possibilities for shortening the supply chain, helping users localize work, take advantage of smaller-volume opportunities and pivot quickly to face challenges.

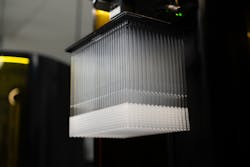

“Additionally, there are wider business benefits offered by 3D printing, such as the ability to have distributed manufacturing with lower logistics costs and being able to produce multiple different parts on the same line at the same time,” said James Reeves, the global director of polymer sintering for Voxeljet, which is anticipating the commercial release of its VX1000 HSS printer later this year.

The technologies also give users a way to compete with lower-wage regions, some experts say.

“You want to react faster to the market. That’s one element,” said Fabian Krauss, head of polymer systems for EOS. “The other element is … you want to have a competitive advantage to cheap competitors from [the] Far East.”

The supply chain advantages are among the reasons cited by the White House last year when it touted more than $200 billion of investments in new manufacturing facilities as part of its AM Forward initiative.

Krauss noted that many manufacturers turned to AM technologies during the pandemic, but returned to more conventional processes as economic conditions stabilized.

“In 2020, millions of swabs were 3D printed, right?” he said. “Nowadays, none of them are 3D printed. They all went back to traditional manufacturing.”

While demand for those items has dried up, other opportunities exist.

Krauss cited toymakers are an example of companies that stand to benefit from the ability to use AM technologies to get smaller-volume, new products to market quickly.

If a movie studio decides on the fly to change a character’s appearance, manufacturers using 3D printers can respond immediately, while injection molders still are scrambling for new tooling.

“If the movie character changes because Pixar thinks it needs to have a different hair color or hairstyle, your mold would need to change,” Krauss said.

3D printing is a more agile approach for both manufacturers and users of the parts they make.

Hospitals, for example, can make implants right where they’re needed, said Victor Roman, managing director of Arburgadditive GmbH, which recently released its largest AM machine, the Freeformer 750-3X.

Or, in the case of a situation Rosman recounted, manufacturers can make parts in-house to avoid issues they might be experiencing with suppliers.

“A Fortune 500 manufacturing company,” she recalled, “struggled around a specific part of their supply chain … the lead time became nine months. So, they started 3D printing [it]” — a process that took just days.

Because manufacturers can use the technologies to decentralize production, AM also represents the opportunity to reduce the environmental and economic impact of transporting products that previously required a long supply chain.

AM contributes to a leaner supply chain, in which manufacturers can create parts on demand, rather than having to rely on suppliers, said Phil DeSimone, a member of the CEO’s office and co-founder at Carbon.

That advantage could give a boost to some companies’ green bona fides.

“By manufacturing at the point of need, you’re helping that local economy, you’re reducing your carbon footprint because you don’t have to transport these things everywhere from here to there to everywhere,” said 3D printing expert Brent Stucker, who in May started his own firm, 3DX Consulting.

In the wake of an era defined by disruption, 3D printing provides one strategy for insulating business from future shocks, with the ability to take advantage of new opportunities as they arise.

By opening the door to lower-volume work, manufacturers can better diversify their business, Stucker said.

“A lot of industries out there have cyclical demand right now, due to complexities of the marketplace and what’s going on in the world right now,” Stucker said. “And, so, in additive manufacturing, what you often find is that, as certain industries are in a slump, other industries are taking off.”

Karen Hanna, senior staff reporter

Contact:

3DX Consulting LLC, Park City, Utah, 435-363-5197, brent.stucker@outlook.com

Arburg Inc., Rocky Hill, Conn., 860-667-6500, www.arburg.com

Carbon Inc., Redwood City, Calif., 650-285-6307, www.carbon3d.com

EOS North America, Pflugerville, Texas, 512-388-7916; Novi, Mich., 248-306-0143, www.eos.info/en

Tali Rosman, [email protected], via Linkedin at www.linkedin.com/in/talirosman

Voxeljet America Inc., Canton, Mich., 734-808-0025, www.voxeljet.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.