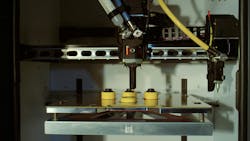

S300X-LIQ21/LIQ11 Manufacturers can use this industrial silicone 3D printer from Lynxter, Bayonne, France, to make parts from medical and industrial silicones, as well as PU materials. Applications include the production of surface treatment masks and caps, custom seal printing, emergency repairs and soft robotics. The printer is equipped with two toolheads as part of an Independent Dual Extrusion (IDEX) system. This allows it to handle both a main component, as well as a secondary component for water-soluble support structures. Its large-capacity cartridges allow it to print large parts or several small ones in complete autonomy, reducing the need for intervention. Meanwhile, its filtered, heated and silent chamber ensures the safety and comfort of its user. In the U.S., Agile Manufacturing distributes the printers.

What’s new? Upgrades being rolled out this year for the printer, which hit the market at the end of 2023. The upgrades include improvements to the software and hardware and a new range of medical-grade COPSIL silicone materials.

Benefits Greater ease of use and faster speeds. The software update provides integrated visual guidance and step-by-step procedures for users, while the hardware update enables faster printing speeds and significantly reduced printhead changeover times. According to Lynxter, the printer is compact, reliable and robust.

Agile Manufacturing, Beaverton, Ontario, 905-852-0794, https://agile-manufacturing.com/

Vital Statistics

|

Dimensions |

About 3.3 feet by 2.4 feet by 3.3 feet |

|

Build volume |

About 11.8 inches by 9.8 inches by 7.9 inches |

|

Heated build plate |

68 degrees Fahrenheit to 176 degrees Fahrenheit |

|

Heated enclosure |

68 degrees Fahrenheit to 104 degrees Fahrenheit |

|

Layer height |

50 microns to 1mm |

|

Maximum tool speed |

About 1.6 feet per second in the X and Y directions, and 1.6 inches per second in the Z direction |

|

Price |

About $42,000 |

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.