What you'll learn:

- The ability to build extremely precise tooling is giving U.S. companies like Guill Tool, ATM and the Velocity Group a competitive edge.

- Companies are leveraging additive manufacturing, in-mold automation and complex cooling channels to produce high-performance tooling.

- Toolmakers are diversifying services to stay resilient — offering prototyping, automation systems, end-to-end manufacturing, even military contracts.

- U.S. firms emphasize IP protection, close collaboration and rapid turnaround as reasons to choose domestic tooling partners over lower-cost offshore options.

- Success depends not only on equipment but also on deep engineering expertise.

By Karen Hanna

The request was demanding. At first blush, perhaps too difficult.

When a customer needed tooling for tubing with just a hair’s breadth of a wall, Thomas Baldock, a sales manager for Guill Tool, initially demurred.

But for U.S. tool makers trying to survive in a competitive market, making a Herculean effort to satisfy Lilliputian tolerances is all in a day’s work.

That was good news for Guill Tool, but better news for users of the tubing — neurosurgeons performing procedures on babies, even in the womb.

As the West Warwick, R.I., company and other tool makers look to capitalize on reshoring momentum, they’re touting their precision, broad capabilities and expertise to offset cost advantages that might drive prospective customers elsewhere.

Narrow tolerances

In an industry where small deviations make all the difference, precision is everything. Competing on price alone is not sustainable.

Tool makers know there’s very little room for error. It’s a point of pride — and a matter of survival.

“That is a challenge to stay competitive, because if you mess up one piece of steel, you’re that close to breaking even and then going under,” said Victor Cohen, a principal engineer at Clearwater, Fla., company American Tool & Mold (ATM) Inc.

Jobs sometimes come down to five decimal places, said Kent Savage, the founder and executive chairman of the Velocity Group, which like both Guill Tool and ATM, has done work involving medical applications.

Savage pointed out that the ubiquity and ease of use of some medical devices obscure the precision that was necessary to create them.

His Byesville, Ohio, plant touts the ability to do it right — as well as to protect the sensitive intellectual property involved in the product’s design and manufacture. It specializes in sensors, electronics and components for the aerospace industry.

“We’re working with the manufacturers to provide injectors that can be used by consumers, and they need the right mix every time. That sounds easy. And it’s very simple to use once it’s designed, but the design and the manufacture, it’s not [easy]. It has to be very precise, and it’s the intellectual property ... if you let that loose, if the manufacturer lets that loose out into the wild, then others can see, ‘Oh, here’s how they solved that problem,’ and that is a big concern,” he said.

Tech support

Facilitating that level of precision is technology, developed by other suppliers as well as in-house. For some, key equipment includes additive manufacturing technologies, as well as in-mold components and automation, cited by several tool makers.

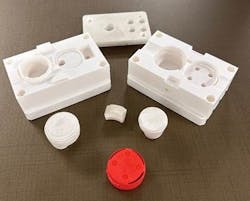

ATM, for example, is using a new 3D metal printer from Mantle Inc., San Francisco, to print components with sophisticated internal gates and cooling channels that would be challenging or impossible to machine. The company also can print tiny characteristics, such as raised lettering, that would otherwise require a laborious electrical discharge machining (EDM) setup.

Improved cooling channels make the mold more productive, Cohen said.

“It’s also helping our customer who runs the mold run faster and get better-quality parts," he said.

While limited by the printer’s build volume, ATM, which specializes in tooling for caps and closures, sees a lot of promise in the technology, according to company officials.

Discussing diagrams of molds ATM has produced with the printer, plastics engineer and mold designer Jerry Jones highlighted one particular sector and said, “There wasn’t really a great way to get water up in there. Maybe you could do some kind of ring of bubblers, but it would be a nightmare.”

But, with the printer, it was easy — and fast.

The process involves printing, then sintering in an oven, and eliminates the need for most post-processing steps, or cutting steel.

All that saves a tremendous amount of time, Jones said, “not only other machines — we have more availability — but we’re also optimizing our tool makers’ time.”

For some tooling makers, in-house technologies also are important selling point.

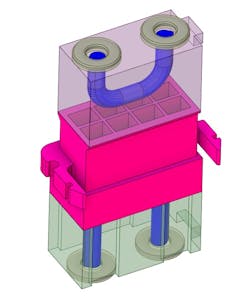

For instance, StackTeck recently scaled up its PiCool technology for use in 144-cavity molds, and it continues to advance its collapsible core mechanism for molds, which allows them to produce undercuts and lips on lids, like the ridges on paint cans or detergent caps.

“The first generation, developed over 20 years ago, was broadly used in in industrial applications. But now with Gen 2, we can go to deeper undercuts, different part geometries, and that’s opened up a window now to expand and scale up the product line,” said Mike Gould, who recently was named CEO of StackTeck.

The newest patent-pending design allows an undercut size that is at least double, and in some cases more than double, the size of previously achievable undercuts, said Jordan Robertson, VP of business development and marketing.

The process means features that might have been molded separately, then attached in separate steps, can be produced all in the same mold.

Guill Tool, too, offers commercial products that make the job easier.

One innovation that’s become a calling card is a cam lock that makes assembling and changing out extrusion dies easier.

“One of the things that our customers complained about was the way that dies are assembled and put together with hardware, with socket-head cap screws. You have to take the end cap in the front off and the end cap in the back off, and then take the insides of the die assembly out for cleaning and maintenance and whatnot, and changing sizes and colors,” Baldock said.

Depending on the number of changeovers a plant performs, the cam lock can save hours of labor and lost machine time.

Diverse portfolio

In a competitive market, some tooling makers are looking beyond one discipline to make their mark — they’re spreading their wings to offer more to their customers, or branch out into different segments.

“Diversity in services will be important. Adherence to best-quality assurance practices has always been important and will continue to be so,” said John Berg, director of marketing, and Greg Gierach, VP of sales, in a joint statement to Plastics Machinery & Manufacturing, from Dynamic Tool Corp., where they work as director of marketing and VP of sales, respectively.

That's definitely the philosophy at ATM, which employs about 200 people. In addition to its Mantle printer, it has Form 3 and Form 4 stereolithography (SLA) printers from Formlabs, Somerville, Mass., for prototyping — a new division at the company — to accentuate injection molding capabilities. As Cohen explained, “That’s really where your margins are in this industry. The margins are very tight on mold building.”

While its tooling tends to be for small parts, ATM injection molds a much broader portfolio of products; it seldom provides end-to-end services.

Cohen said the prototyping division, called ATM-X, opens new avenues for the company and customers.

“They’re not only rapid prototyping, but they’re rapid manufacturing, which is really going to help us go into the next stage of manufacturing at ATM, from traditional, conventional subtractive machining, but to additive manufacturing and helping us be more competitive, which is what we need,” he said.

Injection molding also is important to the Velocity Group, which offers end-to-end services.

With its integrated services, the Velocity Group’s 100 or so employees can work with customers to optimize every stage of the manufacturing process, Savage said.

“We work very closely to say, ‘How is the most efficient way to manufacture this part?’ Sometimes our engineers [work] with theirs and say, ‘Well, if we did it this way, you would get a more efficient result, a faster result, higher quality,’ things like that, that their engineers that were just designing [it] ... weren’t thinking about yet."

At Decatur Mold Tool & Engineering Inc., Rhonda Lustenberger, majority owner and president, also is focused on finding ways to improving its market position. That's meant expanding beyond the volatile automotive industry.

Even with that goal, though, she acknowledged other shops affected by turmoil in the industry could take a bite out of her business — if it’s not proactive.

“Even though our market share of auto has been reduced to 35 percent, which is about where I want it to stay, if we have competitors that were 100 percent automotive, and now they can’t maintain any volume because that volume is down, obviously, they’re hunting in other markets as well, which impacts us.”

According to Lustenberger, just a few years ago, the automotive industry accounted for about 60 percent of Decatur Mold’s business.

Meanwhile, other companies, including Guill Tool and StackTeck, stay busy with side gigs.

Guill Tool's Plan B is unique — it supplies parts for the U.S. Navy’s nuclear submarine program, a project that in recent years has surpassed extrusion tooling as its main business.

In late May, Gould discussed the outlook for business segments spun off StackTeck's original focus on injection molds. Since 2019, the company has devoted teams to building automation, complete with vision systems, expanding its mold offerings to include molds for PET preforms.

In addition to creating new systems, those teams perform restoration of existing systems.

“In the past, on the mold design side, we were obviously looking for sensors and ways to sense and control the actions of the mold for safety, protect the mold itself and the molding machine,” Gould said. “And now we’re talking about integrating those same features to actually perform functions like in-mold closing, unscrewing, part removal, what we call in-mold automation.”

Tech support

That can-do-everything attitude comes down to two factors: Technologies and human expertise.

To stay competitive, tool makers tout both.

“There’s one level to say, ‘Here’s a print, do you have the skilled machinists and engineers to make what was given to you?’ ” Savage said. “We have the highest-level and the latest five-axis milling machines, CNC machines and so on, the EDM capabilities, all the things that are necessary to be a top-quality toolmaker, but we also have decades of experience in how to design for manufacturing.”

Like other tooling makers, the Velocity Group knows what’s at stake — those decimal points of deviation carry a lot of weight.

Succeeding where others can’t is one way the company is trying to distinguish itself, according to Savage, who described a medical device the Velocity Group produced.

“It's for chemotherapy, where it's got 29 injector needles that are all on pins and springs. It's very, very precise.”

The other manufacturers’ devices looked good but didn’t perform well after initial tests.

But, for tooling makers and manufacturers like Guill Tool and the Velocity Group, those high stakes are home turf.

"You’re talking about people’s lives here,” Savage said. “That has to be right.”

Contact:

Guill Tool & Engineering Co., Inc. West Warwick, R.I., 401-828-7600, https://guill.com

StackTeck Systems, Brampton, Ontario, 888-700-8555, https://stackteck.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.