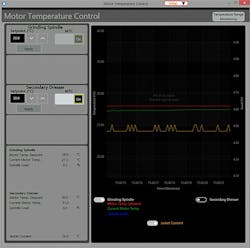

TapX Motor Temperature Control (MTC) This Anca technology allows operators to set the spindle temperature for production, and the machine automatically monitors and maintains that temperature. By stabilizing the spindle's thermal environment, MTC removes fluctuations caused by thermal growth, ensuring greater precision and consistency in tap production.

What’s new? The MTC, now available as an upgrade to Anca CNC machines, which can be used by mold makers for milling, turning, tapping, boring and engraving applications.

Benefits More accurate and better quality and finish of the tap. Use of the MTC significantly improves outer-diameter consistency over a batch, leading to taps with better surfaces, and higher-quality, more-durable threads. In addition, the MTC reduces cutting forces and improves the lifespan of the tooling.

Anca Inc., Wixom, Mich., 248-926-4466, https://machines.anca.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.