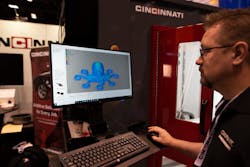

Extruder ensures fast printing of large parts

What’s new? The availability of the Pulsar pellet extruder, from Dyze Design, LeMoyne, Quebec. The large-scale, high-flow plastic pellet extruder is designed as an optional extruder for the MAAM, but is compatible with any large-scale 3-D printer or even robotic arms. To maintain optimal melt temperature, the extruder features a triple-heat-zone design. The top section receives cold pellets and generates more heat to melt them. Then, the middle zone stabilizes the polymer at a precise temperature. Finally, the nozzle heater ensures even flow.

Benefits Cost-effective, quick printing of parts with dimensions of about 3.3 feet in all directions. The nozzle is abrasion-resistant and can handle higher temperatures than the MAAM’s other extruder, which is designed for 2.85mm filament and a maximum temperature of 842 degrees Fahrenheit.

Cincinnati Inc., Harrison, Ohio, 513-367-7100, www.e-ci.com

Dyze Design's Pulsar extruder |

| Weight | 15.4 pounds |

| Nozzle diameters | 1mm, 3mm and 5mm |

| Maximum throughput | 5.5 pounds per hour |

| Maximum temperature | 932 degrees Fahrenheit |

| Heating power | 800 watts |