Patent Report: 3-D printer mixes filaments

3-D printer A fused deposition modeling (FDM) 3-D printer that provides better mixing of multiple filaments made of different resins is the subject of a patent application submitted by Battelle Memorial Institute, Columbus, Ohio.

Many applications for 3-D printing “exist where specific mechanical, thermal or chemical properties are needed that cannot be met with the available feedstock selection,” the application states. “There are different types of filaments available with different properties, which may require different temperatures to print. Two filaments, such as filaments composed of different materials, may be mixed to achieve a particular homogeneity and/or particular consistency.”

However, existing mixing nozzles for 3-D printers do not always adequately mix polymers of dissimilar compositions, according to the application.

The invention can homogenously mix materials with dissimilar characteristics and melting points in controllable ratios. For example, it can combine a conductive and a non-conductive filament; a soluble and an insoluble filament; or a flexible and an inflexible filament, according to the application.

Other advantages include improved material mechanical properties and extrusion pressures great enough to extrude filaments that are viscous.

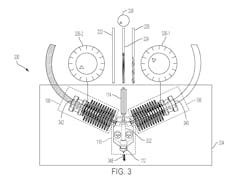

The printer has an extruder with a heated chamber in its hot end, and a mixing element that rotates inside the chamber in order to achieve the shear forces needed to mix the molten plastics. The mixing element also can have a secondary driving mechanism to assist with extruding the molten plastics. The mixing chamber has features that include an interior surface with a rough texture, a surface with a helical flute and a baffle. Additionally, there is a heater block to heat the mixing chamber.

Patent application 20200207021; published July 2