3D Platform unveils industrial-class Excel 3-D printer

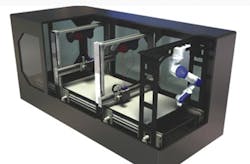

3D Platform, a maker of large-scale, industrial-class 3-D printers, unveiled its Excel-series additive and subtractive manufacturing center during Rapid + TCT in Pittsburgh.

The system has multiple patents pending, officials said, including for controls, multi-gantry options and some technologies related to the extruders. It is a fused-filament-fabrication printer with a build area of 4 feet by 4 feet by 8 feet and a high-volume extruder system. Five models are available: a 100 series, 200 series, 300 series, 400 series and a Custom series. Depending on customers' requirements, the build area can be scaled up. The material throughputs range from about 3.3 pounds per hour to 121.3 pounds per hour per gantry. The machine has parallel gantries, and users have the option of additive or subtractive manufacturing; the use of robotics also is an option for individual or simultaneous multi-process machining.

The options for extruders include the HFE 900, a 6mm-spool-fed extruder that can produce up to 4.4 pounds per hour. The company's bigger extruder models are called Extruder Size 1, Extruder Size 2, Extruder Size 3 and Extruder Size 4. Extruder Size 1 is pellet-fed and can produce up 13.2 pounds per hour; its Extruder Size 2 also is pellet-fed and can produce up to 26.5 pounds per hour. The maximum throughputs of the pellet-fed Extruders Sizes 3 and 4 are 48.5 pounds per hour and 121.3 pounds per hour, respectively.

Entry-level, single-gantry versions of the printers range from $300,000-$400,000. A three-gantry configuration with a pellet-fed extruder and robotics would run roughly $1.3 million.

For estimated pricing, potential customers can visit https://3dplatform.com/configurator/ and plug in their machinery preferences.

Products that can be made with the technology include car bumpers, car frames and boat hulls. Even production of a turbine blade is possible; at Rapid, 3D Platform showed an illustration of a turbine blade made on a Custom-series machine that was 17 feet by 124 feet by 12 feet tall.

"We're big, we're fast, we're affordable," said John Good, VP of global sales and marketing for 3D Platform. "Everybody wants to print faster."

The Excel series is based on what is known as open-market, or open-source, software. The package doesn't come from 3D Platform; instead, the company recommends an affordable software called Simplify3D, though other software programs can be used. Users also can buy filament from any source instead of being captive to their printer supplier for materials.

"I have had people who cannot afford to run their machines," Good said. "One of the reasons we embraced open-market concept is because of the affordability."

Good said the fastest-growing segment for 3-D printing is in manufacturing support. Examples of that include the production of jigs and fixtures. Parts can be used in assembly operations, for example, when there is a need to hold the part in a certain orientation and not scratch it.

Angie DeRosa, managing editor

Contact:

3D Platform,Roscoe, Ill., 779-771-0000, www.3dplatform.com