Mark G. Sellers knew in high school that he wanted to run his own business.

Through the Junior Achievement program, he met someone who steered him into tool and die making, which led to injection mold making, then injection molding, then blow molding, then manufacturing molding machinery components and automation equipment.

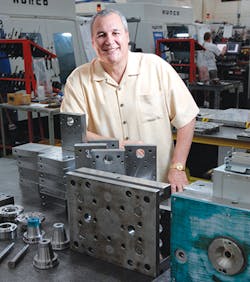

Today, at age 61, he is the majority owner of MGS Manufacturing Group Inc. with 1,400 employees in three countries. Sales this year are expected to hit $200 million.

His secret: Every time his business ran up against obstacles, he and his team aggressively looked for ways around them. Along the way, the company has gained a worldwide reputation for high-quality work on the most demanding projects. Sellers recently answered questions for Plastics Machinery Magazine Editor Ron Shinn.

How did you get into the plastics industry?

SELLERS: In high school, I was in Junior Achievement and Distributive Education and was president of the local chapter of Junior Achievement. Through Junior Achievement, I had met the people at Universal Foods, who introduced me to J.L. Clark at a company then known as Plastronics. He was looking for someone to bring along, have them start at the bottom as a tool and die maker, then learn engineering and eventually how to run the company. He planned to retire in 10 years.

When I started I didn't even know what a tool and die maker was. I actually thought I was applying for a foremanship. But it was really an apprenticeship.

So you knew in high school that you wanted to be an entrepreneur?

SELLERS: I had always wanted to be in business. In Junior Achievement, I had written that 10 years out of high school I would be running my own company. This apprenticeship sort of fit into that idea for my future, plus they were going to pay me to go to community college. It seemed like a good deal for a young kid.

Did you enjoy the work?

SELLERS: I loved it. It came naturally for me.

What was the next turning point in your career?

SELLERS: The guy I was working for, the one who was eventually going to put me in charge, had a heart attack. All of a sudden, the bottom fell out, and that set things in motion. I had to go find work for the shop. It dawned on me that if I was going to do that, I might as well be finding jobs for myself.

Did that lead to you starting your first company?

SELLERS: Yes. We started on my birthday, May 2, 1982, and called the company Moldmakers Inc. We started in a 1,500-square-foot garage down the street from where I was working in Butler, Wis. We bought a few pieces of equipment at an auction and started taking orders and cutting metal.

How many people were there at the beginning?

SELLERS: Three. Myself and two partners. I was working in another tool and die facility on the second shift because I had to pay the bills and the three kids needed shoes.

How did you fund the startup?

SELLERS: Each of us got approved for $25,000 second mortgages on our houses. Plus, we had saved up about $10,000 to $15,000 each.

What were the early days like?

SELLERS: From the beginning, I went out and picked up quite a bit of work. After three or four months, I was able to quit my other job because we were working 24/7. In September, we hired two more tool makers and two apprentices.

What was the first mold you made for a customer?

SELLERS: Dremel had a portable shoe polisher. It had a little cone that the brush or pad fit on. We made the mold for that piece. New Berlin Plastics was the molder. We got $11,500 for the job, but they made some changes and we ended up getting $12,000.

Skilled mold makers can be difficult to find. Where did you find them as the company grew?

SELLERS: This area of Wisconsin is good for tool and die people. There are highly skilled people with a good work ethic. I knew a lot of people and we were looking for people with eight-10 years of experience. Sometimes you could have a cocktail with a guy and he would complain about the place he worked, so I'd say "If you are so unhappy, why not come over to us and give it a shot?" Word got around that we were busy and a good place to work.

What caused Moldmakers Inc. to grow?

SELLERS: We were never late on a project. In the beginning, we couldn't afford to be late because we needed to get paid. We would finish our part of a program in 12 weeks when the program called for 20 or more weeks. The other guys in the program weren't done, but we were. Word got around that we could do a program in a hurry.

What was your life like at that point?

SELLERS: We were making good money but busting our butts. I'd go home in the mornings to help get the kids off to school and make my appointments to call on customers in the middle of the day. Then I'd come back to the office and work on quotes, then cut steel. We worked all night. We would sleep in the shop. That's what you had to do to pay the bills in the beginning.

Did you plan to grow into multiple businesses or did you take advantage of opportunities as they came along?

SELLERS: On Jan. 15, 1988, we moved from Butler to our new facility in Menomonee Falls — 15,000 square feet. I didn't know how we were going to fill up that much space, but a year later we were expanding it.

We developed a design business — Prototype, Molds & Design — because all of the big companies in the industry were going the other way. They wanted to specialize. So we started the design company our customers said they needed.

Then some of our customers needed specialized manufacturing services, so we started Statistical Plastics Corp. as a testing, molding and inspection services business.

Next came TecStar Mfg. Co. to do injection molding, then Universal Multishot Systems to build portable injection units and rotary platens.

We started MGS Automation, first to build our own custom automation equipment, then for our customers.

In 2012, we launched MGS Sampling to provide mold functional sampling and short-run services and validation of turnkey production cells.

What did your customers think about you competing with them in injection molding?

SELLERS: We started molding with SPC and some of our customers got nervous about what we were doing and cut us off. That sort of forced us into starting TecStar. I went directly to the OEMs for molding work, and fortunately they preferred our services.

Did the good relationship you had with OEMs help launch the injection molding business?

SELLERS: Yes. From the beginning, I always sampled our tools. I didn't know any better. I remember coming in with parts and the customer asked me where I got the parts. I said I ran them. "What are you doing with my tool?" he asked. I told him it wasn't his tool yet because he hadn't paid for it and that I had to make sure it functioned correctly. The customer looked at the parts and said he didn't know if he could make them that good. So I said, "I can take care of that, too!"

How did you get into blow molding?

SELLERS: When we opened our second molding facility in Libertyville, Ill., our customer, Paslode Cordless Tool Group, needed a blow molded case for their nail gun. We bought a blow molder and started doing blow molding. Pretty soon we were winning awards, so we did more of it.

You acquired All West Plastics in Antioch, Ill., in 2006. Was this your entry into medical molding?

SELLERS: We were molding a lot of medical products, but acquiring All West was our entry into clean-room molding and all the other certifications. Now it is more than 40 percent of our total business and we plan to grow it to 50-60 percent.

What led you to start molding in Mexico in 2008?

SELLERS: Three of our high-end customers requested we join them. We were fortunate to find the plant in Chihuahua that we acquired. It was clean and organized, and we converted it for our use. We took that plant from about $4 million a year in sales to about $36 million. It has been a good experience and good business.

During the past 33 years, you have been through a lot of business cycles and one very tough recession. How have you continued growing through the tough times?

SELLERS: We have always been aggressive in forward thinking. When the bottom fell out on different products and orders, we have been able to focus on the future and fast-track development of whatever opportunity we could find. I think that has been the reason for our diversity and development. Generally, newer products were growing fastest and we were aggressive in going after them.

MGS has a strong staff. How did you find them?

SELLERS: I have always said I wanted people in the top 30 percent. If you are not in the top 30 percent, go somewhere else. Those other places need employees, too. We just keep developing them and training them, so all these smart people just keep getting smarter. There's not too much they cannot do. I guide them, point them and provide the right resources. A lot of our management people served their apprenticeships with us. About 75 people have gone through our apprenticeship program and half are still with us. That's pretty special to me.

Do you consider yourself a businessman, a mold maker or some combination?

SELLERS: A tool, die and mold maker and business entrepreneur, CEO and toilet cleaner!

How would you like to be remembered?

SELLERS: As a man of good heart who kept his word and did his best. My reputation is my bond and the most important thing to me. I did a lot of crazy deals on a handshake. Fortunately, almost every one of them turned out pretty darn good.

Ron Shinn, editor

About the Author

Ron Shinn

Editor

Editor Ron Shinn is a co-founder of Plastics Machinery & Manufacturing and has been covering the plastics industry for more than 35 years. He leads the editorial team, directs coverage and sets the editorial calendar. He also writes features, including the Talking Points column and On the Factory Floor, and covers recycling and sustainability for PMM and Plastics Recycling.