Patent Report: Remcon invention improves pallet production

Mold core. An asymmetrical mold core for creating specialized, rotationally molded pallets is the subject of a patent awarded to Remcon Plastics Inc., Reading Pa.

Hand-operated pallet jacks are often used to transport plastic pallets. The forks of the pallet jacks have wheels that enter holes in the pallets; making the bottom of the pallet openings curved is desirable so that the wheels don’t have to go over a rectangular bump, the patent states.

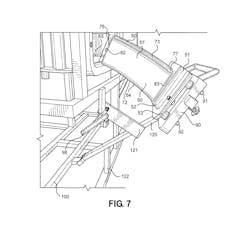

The mold core described in the patent consists of a base that attaches to a frame in a rotational mold; curved top and bottom sections; two side sections; and a face.

When the plastic in the mold — typically PVC — hardens, it shrinks around the mold core. If the curves of the top and bottom sections were parallel, the shrinking plastic would seize the mold core and make it difficult to remove, according to the patent. So that the mold core does not get embedded or trapped in the hardened plastic, the upper curve is oriented around a different center of rotation than that of the lower curve, thereby creating a core geometry where the upper curve and the lower curve are not parallel. Therefore, the two curves are divergent towards the base assembly, creating a “rotational draft.”

The mold core can be made of aluminum, steel or other metals, and can be adapted to produce pallets with differing dimensions, according to the patent.

Patent 10,786,931; issued Sept. 29