NPE Booth S21111

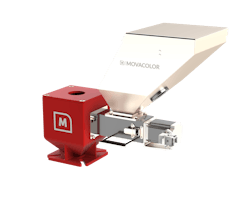

MDS Movacolor’s volumetric feeders can be combined with other units, and can be specifically tailored to fit the requirements of different production processes including injection molding, extrusion, blow molding and compounding. MDS feeders can handle a wide variety of materials, from granulates and microgranulates to free-flowing powder, at up to 158 degrees Fahrenheit. Movacolor’s VoluTouch controller features an intuitive 4.3-inch capacitive touch screen that can control two feeders.

What’s new? The feeder line, which makes its North American and Latin American market debut at NPE 2024.

Benefits Cost-effective, high-performance dosing. The MDS volumetric feeder’s stepper motor is efficient and compatible with dosing tools that allow it to operate from 0.1 revolution per minute (RPM) to 200 RPM in increments of 0.1 RPM, for feeding capacity ranging from 0.09 pound to 159 pounds per hour. This precise level of control minimizes overdosing, cutting material and process costs. Cleaning and material changes can be accomplished in 60 seconds, minimizing downtime.

Movacolor, 262-675-3035, [email protected], www.movacolor.com

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.