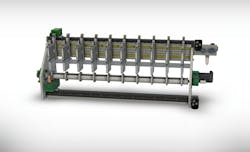

Tidland SmartSlit This automated slitting system from Maxcess is tailored for narrow web applications. It ensures automatic and precise placement of slitting blades, eliminating the need for manual adjustments and reducing set-up time, as well as improving operator safety and ergonomics. Built-in releases allow operators to move knives by hand for clearing web breaks and for maintenance, and to run the entire line manually if the electronics are down. The system is compact and reduces space for parking unused knives, as knives can be individually retracted, either manually or by using the software. Jobs and patterns can be stored for reuse.

What’s new? The SmartSlit. It is available for new machines or as a retrofit, in shear, crush and razor configurations.

Benefits Flexibility, robust and accurate knife positioning, and ease of use.

Maxcess International, Oak Brook, Ill., 844-629-2377, www.maxcessintl.com

Vital Statistics

|

Maximum web width |

48 inches |

|

Maximum number of knives |

24 |

|

Minimum slit width |

0.86 inch |

|

Position accuracy |

Plus or minus 0.12mm |

|

Positioning speed (6 knives) |

Less than 1 minute |

About the Author

Lynne Sherwin

Managing Editor

Managing editor Lynne Sherwin handles day-to-day operations and coordinates production of Plastics Machinery & Manufacturing’s print magazine, website and social media presence, as well as Plastics Recycling and The Journal of Blow Molding. She also writes features, including the annual machinery buying survey. She has more than 30 years of experience in daily and magazine journalism.