SABIC targets automotive market with new materials

By Karen Hanna

Resins intended to meet the need for high-tech components including batteries, optics and navigation-system antennae are among SABIC’s latest offerings for the evolving new-vehicle market.

The offerings include resins that take aim at some of the particular challenges of hybrid or electric vehicles (EVs); a polyetherimide (PEI) for use in vehicle lighting; and compounds designed for use in second-generation automotive global navigation satellite system (GNSS) antennae. Also new are two short-glass-fiber-reinforced PP compounds for use in structural components; and a portfolio of mineral-reinforced PP compounds for foam injection molding.

EVs fuel need for new resins

In an announcement of the launch of SABIC’s Noryl NHP8000VT3 polyphenylene ether (PPO)-based resin, Joshua Chiaw, business-management director for SABIC’s LNP and Noryl brands, noted the urgency to develop materials to meet the changing needs of new-vehicle makers.

“Transitioning from standard, 400-volt EV batteries to higher voltages offers the potential to shorten charging times, extend range and improve energy management within the vehicle,” he said. “However, designing higher-voltage batteries requires the invention of breakthrough materials, such as our new Noryl resin for insulation films.”

With its ability to withstand charges of 600 volts or more, Noryl NHP8000VT3 is an effective alternative material for use as an insulation film in EV batteries, to offer protection against short circuits and fire. It can be processed by extruders and thermoformers at thicknesses of just 0.25mm, with better mechanical strength than PP. PC, the other material typically used in such applications, doesn’t perform as well as the new Noryl resin when exposed to high voltages, SABIC said.

At high voltages, ultra-thin film made from the non-brominated, non-chlorinated Noryl resin exhibits better flame retardance than either PC or PP. This allows for up to 40 percent weight reduction when using the Noryl resin, compared with applications that use PC.

Overall, SABIC said in press release, the resin advances EV battery technology “by contributing to occupant safety, weight reduction and higher efficiency for extended range.” In addition to its applications in battery film, it might also be useful for the insulation of metal EV busbars, using overmolding or insert molding processes, the company said.

Another resin designed for use in EVs, as well as hybrid and plug-in hybrid vehicles, the new 3-micron Elcres HTV150A from SABIC Specialties can be used in dielectric film capacitors in traction inverters, onboard chargers and electrical compressors. Previous versions could be processed at thicknesses of 5 microns; the newest version can be used in films of just 3 microns. It can handle frequencies of up to 100 kilohertz and temperatures between minus 40 degrees Fahrenheit and up to 302 degrees Fahrenheit — more than 25 degrees hotter than traditional PP films can tolerate.

“Our new 3-micron film can help customers design smaller package sizes that potentially avoid the use of active cooling systems associated with films that perform at lower temperatures. As OEMs design electric and hybrid vehicles to operate at specific voltages, the new 3-micron film can help with differentiation by providing tailored properties,” said Greg Stoddard, technical director for resins and new chemistries, in a SABIC press release.

Materials for accessories

SABIC also has released materials for vehicle accessories, including lights and navigation systems.

It’s also appropriate for use in components in automotive LIDAR sensors, drones, robots, optical modems and optical cables.

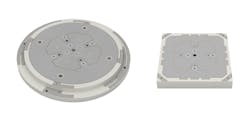

Boasting thermal resistance and qualities that facilitate electroplating, design freedom and production efficiency, SABIC Specialties business unit's new LNP Thermocomp resins, ZKC0CXXD and ZKC0DXXD, can be used as alternatives to ceramics in antennae, Chiaw said in a press release.

“Our new LNP Thermocomp compounds can help antenna manufacturers achieve superior signal gain compared to ceramic substrates. They also provide flexibility to produce smaller parts with the same performance as ceramic, or equal-size parts with better performance,” he said. “This remarkable combination of improved signal capture and design freedom, plus system cost advantages, can help propel innovation in GNSS technology — a keystone of occupant safety today and autonomous driving in the future.”

PP materials for structural parts

Five new PP compounds — the G3430X and G3440X short-glass-fiber-reinforced grades for demanding under-the-hood, exterior and interior applications, from SABIC’s Petrochemicals business unit — fill out the company’s stable of new offerings for vehicles.

They can be used in brackets, seat structures and center consoles, as well as in applications that require thin walls, allowing for lightweighting.

In certain low-temperature applications, the new grades might be able to replace long-glass-fiber-reinforced PP.

Abdullah Al-Otaibi, GM for engineering thermoplastics and market solutions, said about the G3430X and G3440X grades: “We have set new industry benchmarks for robust performance and thin-wall capabilities in short-glass-fiber polypropylene, providing critical advantages in the face of escalating automotive requirements.”

Karen Hanna, senior staff reporter

Contact:

SABIC Americas, Houston, 800-845-0600, www.sabic.com/en