Patent Report: Resin slides on water film in Coperion conveying system

Conveying system. Coperion GmbH, Stuttgart, Germany, is seeking a patent for a system that pneumatically conveys plastic resin while reducing pressure peaks and resin abrasion and improving process stability.

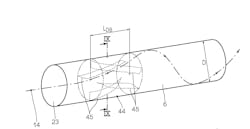

The invention conveys the plastic granulate via a humid, pressurized conveying gas, typically air. It includes a humidification unit and a condensation tempering unit, which controls the temperature of the conveying line so that some of the moisture in the gas condenses on the internal wall of the conveying line, forming a slippery film. The condensation tempering unit can be arranged along sections of the conveying line, or over its entire length.

The patent application states “moisture contained in the conveying gas can be selectively condensed for improved conveying conditions, at least along a section of a conveying line. At least partial condensation of the liquid enables a liquid film to form on an internal wall of the conveying line. The liquid film serves as a sliding film for the plastic granulate. By means of the sliding film, the friction of the particles of the plastic granulate on the internal wall of the conveying line is reduced.” This allows for the conveying pressure to be lowered, which improves process stability, reduces conveying pressure peaks and results in less abrasion of the resin pellets.

An advantage of the system is that it can adjust the conveying conditions to accommodate the varying properties of different resins, such as brittleness, stickiness and hardness.

Additionally, the invention can be configured with an evaporation tempering unit that prevents moisture from entering the resin’s destination container at the end of the line.

“It has been found that, owing to the residual heat in the plastic granulate for example, the liquid which is on the internal wall of the conveying line and/or on the plastic granulate, for example, may evaporate. The risk that the moisture will get as far as the target location … is thereby reduced and, in particular, eliminated,” the application states.

The invention may include numerous sensors to measure the ambient temperature, the temperature at the internal wall of the conveying line and the temperature in the conveying line, as well as the humidity of the conveying gas. The information the sensors provide is transmitted to the controller for the condensation tempering unit.

Patent application 20210122587; published April 29