Patent Report: Space-saving invention combines pressure sensor, date stamp

Pressure sensor. In injection molding of both metal and plastics, pressure sensors can optimize the process and improve the quality of the parts produced. Additionally, the use of date stamps is often mandatory for producing parts that require documentation.

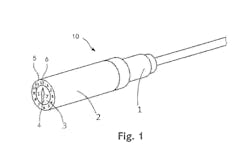

A patent was awarded to Kistler Holding AG, Winterthur, Switzerland, for an invention that combines both of these well-known devices into a single unit.

According to the patent, it is frequently the case that “the installation space for pressure sensors and date stamps within the metal and plastics processing tool is limited in such a way that either a pressure sensor or a date stamp can be installed, but not both together.” This can compromise the quality of the parts produced or preclude the production of certain types of parts.

The patent describes a range of potential embodiments of the invention that achieve the same results and can be inserted into a single hole drilled into a tool.

In one embodiment, a pressure sensor entails a sensor housing that can be connected to the tool, with a pressure transducer inside the sensor housing. The pressure sensor has a two-part front face that forms a portion of the inner surface of the tool cavity and can make a mark on the part. The two portions of the face are adjustable against one another, so the mark they make on the part can be changed to update the date of production or a batch number.

The invention can use any commercially available conventional pressure transducer, whether a piezoelectric, piezoresistive, inductive, capacitive and/or potentiometric pressure transducer, and/or a pressure transducer with resistive wire strain.

The invention could be applied to existing tools as a retrofit, and its adoption offers a number of advantages, including adding more functionality to a tool with limited space, avoiding the need to remove it from an injection molding machine to remachine it, and minimizing downtime, according to the patent.

Patent 10,987,843; issued April 27