Using a screwdriver might seem like a simple task, but it has been difficult to teach a collaborative robot how to do it safely on every try.

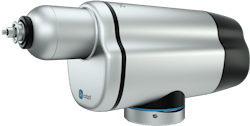

OnRobot, the Denmark-based manufacturer of end-of-arm-tooling (EOAT) for cobots, in late June introduced the OnRobot Screwdriver, designed to work with a wide range of screws and be easy to program so it can be moved from job to job.

“This is one of our most advanced products to date,” said OnRobot CEO Enrico Krog Iversen, in a news release. “We’ve designed an automated screwdriving tool that simplifies a highly complex process for our users, making it cost-

effective and easy for manufacturers to see fast results in terms of high uptime, output, consistency and quality.”

The screwdriver function, which cobot and EOAT manufacturers have been talking about for the past 18 months, represents a big step as cobots evolve to be able to perform more complicated plastics assembly tasks.

The screwdriver works with OnRobot’s One System Solution, a device that provides a mechanical and electrical interface between the arms of many leading robots and OnRobot’s products.

Once the Screwdriver is attached to the robot arm, the screw length and torque value are entered into the program through the teach pendant. The EOAT uses its torque control and embedded axis to automatically calculate the speed and force required to accurately fasten the screw.

The multifunctional Screwdriver can detect if the screw is picked correctly, is the correct length and has been properly inserted during the tightening process. A safety stop is automatically activated if a screw is exposed to excessive force along its axis, with alert lights to notify operators.

Screws up to 1.38 inches long are retracted inside the tool while the robot arm moves and are driven only when the arm is in position. A variety of screw sizes, from M1.6 to M6 and lengths up to 1.97 inches, are compatible with the device.

The Screwdriver has an exchangeable bit system so the screw size can be quickly changed.

Available torque ranges from 0.15 Newton meters (Nm) to 5 Nm. The EOAT is safe to use for electronics assembly.

Screw feeders are available.

Ron Shinn, editor

Contact:

OnRobot Americas, Irving, Texas, 469-586-8384, www.onrobot.com

About the Author

Ron Shinn

Editor

Editor Ron Shinn is a co-founder of Plastics Machinery & Manufacturing and has been covering the plastics industry for more than 35 years. He leads the editorial team, directs coverage and sets the editorial calendar. He also writes features, including the Talking Points column and On the Factory Floor, and covers recycling and sustainability for PMM and Plastics Recycling.