In an effort to broaden its North American plastics automation market share, Yushin America has added a take-out robot for use with injection molding machines with clamping forces of 1,500 tons and greater.

Primary markets for the full-servo robot, which company officials said will only be sold in the U.S., Canada and Mexico, are parts for appliances, cars and industrial equipment. The robot launched in October.

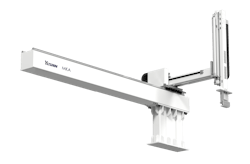

The MKA-2000S was engineered at Yushin’s headquarters in Kyoto, Japan. It has a high degree of rigidity and increased vibration damping to achieve consistent take-out and part-release actions. The arm and kick unit are designed for speed and repeatability. Yushin said that as a result, the model provides take-out times that are 17 percent shorter and cycle times that are 10 percent shorter than its previous large-part robots, such as the RBII-2500S.

The MKA-2000S is a low-profile unit, which makes it a practical option for workspaces with low overhead clearance, company officials said. The robot weighs 3,153 pounds.

The robot is also engineered to reduce its use of energy and air. The servo motors and vacuum circuits are energy-efficient, and the robot monitors and measures its energy usage in real time.

The MKA-2000S comes with Yushin’s E-touch compact controller as standard equipment. It has a 7.5-inch color touch screen and an ergonomic, one-handed grip. The control has several new capabilities: a predictive maintenance feature that monitors the robot during operation and alerts the operator if it detects a problem; a flowchart display that speeds troubleshooting; and an enhanced manual operation screen that groups manual controls for all axes on one screen.

The controller also programs each axis to operate independently, as well as synchronizes cooperative axes of motion, and integrates operations with downstream auxiliary equipment.

Contact

Yushin America Inc., Cranston, R.I., 401-463-1800, www.yushinamerica.com