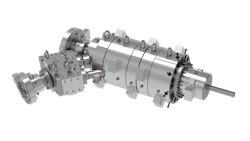

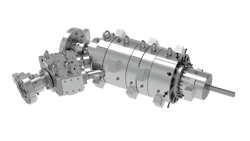

Battenfeld-Cincinnati is rolling out new technologies for pipe manufacturing, with next-generation PVC pipe extrusion heads and a new cutting machine.

The company is upgrading the mono-layer and the multilayer pipe heads in its Spider line with the NG technology. There are numerous sizes available for extruding single-layer pipe with diameters ranging from 6mm to 710mm, and multilayer pipe with diameters from 32mm to 710mm.

The NG pipe heads already have been deployed at some customers’ sites for production testing.

“Their low material consumption and narrow tolerances are delivering impressive results across the board,” Battenfeld-Cincinnati said in a press release.

The optimized design results in more uniform pipe wall thickness, preventing areas that are thicker than required.

“The monolayer NG has optimized material volumes, pressure zones and parallel land to improve the overweight” areas of the pipe, said Paul Godwin, president and CEO of Battenfeld-Cincinnati USA.

In pipe heads that exhibit excellent flushing, material moves consistently, with no stagnation or velocity variation. That’s important because, if the velocity in the melt channels is inconsistent, the thickness of the pipe’s layers will show variations. With the new design, the thickness of each of the three layers is more accurate and consistent, Godwin said.

At K 2019 in Germany, the pipe heads will be presented alongside compatible extruders. The heads are designed primarily to work with counter-rotating twin-screw extruders, but they also can be used with some single-screw extruders.

Battenfeld-Cincinnati also will demonstrate its new DTA 160 cutting machine for cutting polyolefin and PVC pipes to customers’ length specifications quickly, precisely and cleanly.

A highlight of the new unit is that it works without hydraulics, which results in a 60 percent weight reduction compared with conventional systems. Also, it works much faster, the company said.

Bruce Geiselman, senior staff reporter

Contact:

Battenfeld-Cincinnati USA McPherson, Kan., 620-241-6843,

About the Author

Bruce Geiselman

Senior Staff Reporter Bruce Geiselman covers extrusion, blow molding, additive manufacturing, automation and end markets including automotive and packaging. He also writes features, including In Other Words and Problem Solved, for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He has extensive experience in daily and magazine journalism.