Patent Report: Pelletizer produces fewer fines

Pelletizer. According to its patent application, a pelletizer proposed by Bay Plastics Machinery Co. LLC, Bay City, Mich., would create fewer fines, increasing the yield, quality and value of the pellets it produces.

A problem with standard pelletizers is that, while most pellets are successfully directed into the collection chute, some circulate within the cutting chamber and make repeated contact with the rotating cutter. This chops pellets into irregular sizes and creates fines.

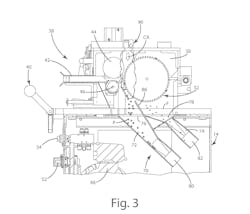

The proposed pelletizer’s design mainly follows convention, with a feed assembly and feed rolls that direct the thermoplastic strands into a cutting rotor located within the cutting chamber.

However, one major innovation of the current design is a discharge chute assembly with two chute sections and a divider plate between them. The mouth of the first chute is located below the cutting rotor, so that the momentum of the cutting action guides most pellets into it. The divider plate, which can be placed very close to the cutter, deflects pellets that would overshoot the first chute without intervention. Fines tend to leave the cutter’s teeth after they have passed the divider plate, and so are directed into the second chute.

A vacuum source can be added to improve the draw of pellets or fines into the correct chute. In addition, in some embodiments of this invention, a nozzle can direct compressed air past the cutting rotor and toward the mouth of the first chute, enhancing the separation of fines from pellets. Also, an ion emitter can be added to improve the movement of pellets and fines.

Patent application 20200164380; published May 28

Patents and patent applications can be viewed at www.uspto.gov

Have you applied for or received a patent? Contact editorial@plastics machinerymagazine.com