Coperion extruders can compound PP for melt-blown mask material

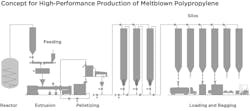

Coperion has validated its ZSK twin-screw extruders for producing PP pellets that are tailored for use in the melt-blown fabrics used to make masks for medical personnel.

The company recently completed tests at its lab in Stuttgart, Germany, in conjunction with Lummus Novolen Technology GmbH, that demonstrated its twin-screw extruders can produce PP pellets with extremely low melt viscosities. Such PP is used to produce nonwoven fabric for use as filter media in masks.

The test results show that both existing and new large-scale extruders can be used for the application. The process represents a milestone, one company official said.

“With this process, the licensees of Novolen are now able to produce these coveted products safely and reliably, without restrictions on the existing product portfolio,” said Sebastian Schwarzer, technology manager for extrusion at Novolen.

Novolen develops and implements process technologies. The newly developed PP compound is based on a raw PP material developed in a Novolen process. Coperion made the necessary adjustments to its extruders so they can produce the PP for melt-blown applications.

The tests used ZSK extruders with ZS-EG side devolatilization units and a screw tailored exclusively for Novolen.

“The combination of a new screw concept for optimum dispersion and a very good degassing, thanks to ZS-EG technology, secures first-class product qualities,” said Coperion’s Heiko Hornberger, head of Team Polyolefins, process technology. “This is achieved with outstanding process reliability, regardless of throughput rates and melt viscosity.”

The Novolen process is used to make PP resins for all kinds of applications, such as pipe extrusion, injection molding, film and fiber. With the recent development, the company’s portfolio now includes resins for melt-blown products. The company licenses PP technology and provides related engineering and technical support and advisory services.

Coperion is supplying the machinery components to licensees of Novolen’s process.

Bruce Geiselman, senior staff reporter

Contact:

Coperion Corp., Sewell, N.J., 856-256-3175, www.coperion.com

Lummus Technology, The Woodlands, Texas, www.LummusTechnology.com

About the Author

Bruce Geiselman

Senior Staff Reporter Bruce Geiselman covers extrusion, blow molding, additive manufacturing, automation and end markets including automotive and packaging. He also writes features, including In Other Words and Problem Solved, for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He has extensive experience in daily and magazine journalism.