Artec rolls out recycling, extruder system

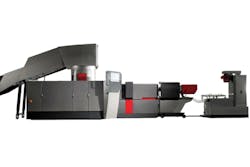

MODUL 500 This modular recycling and extruder system from Austrian Recycling Technology (Artec Machinery GmbH) is configured for a processor's specific type and character of raw material. Artec primarily develops recycling systems that process film waste, fibers and ground stock into granulate at rates from 250 to 2,500 kilograms per hour.

WHAT'S NEW? Six modules (material cutter, cutter-compacter, extruder, degassing, filtration and pelletizing modules) that can be swapped out for optimal recycling of a specific material.

BENEFITS Material is fed, cut and compacted then heated by frictional heat below its agglomeration point. A vacuum removes residual moisture (allowing for the processing of materials with high residual moisture without pre-drying), then the material is pelletized or processed further as melt.

Artec Machinery GmbH, Kematen, Austria, 864-464-0007, www.artec.at