System boasts ultrasonic sealing

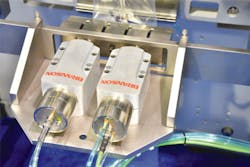

VFFS system Branson Ultrasonics, a business of Emerson, has introduced a vertical form, fill and sealing system for food packaging. The system uses Branson's Balun horn technology, which produces a continuous seal on packages up to 16 inches wide, while maintaining superior amplitude distribution. To make a package, the system passes the film over a vertically oriented forming collar that creates the desired bag configuration. It then seals the edges, fills the package and seals the opening.

What's new? The use of ultrasonic sealing instead of heat sealing, which is the main method used to make flexible packaging.

Benefits Reduced energy and material consumption. Ultrasonic sealing eliminates the need for warm-up time and offers a 75 percent reduction in carbon footprint compared to heat-sealing systems. Narrower seals are also possible, resulting in reduced material consumption. Also, the system is compatible with bioplastics.

Branson Ultrasonics Corp., Danbury, Conn., 203-796-0400, www.emersonindustrial.com