Plastics Recycling Patent Report: RepetCo, Alpla Werke Alwin Lehner

Method for separating multilayer plastics for recycling

A patent awarded to RepetCo Innovations S.L., of Madrid, describes a system and method for separating the layers of multilayer plastics. Such plastics are commonly used in agriculture, industry and packaging.

Current methods for recycling multilayer plastics include steps such as size reduction, weakening the adhesive bond between layers (usually with heat), and separating the layers physically and/or chemically. Drawbacks posed by these methods include their resource demands, such as high energy requirements and the use of toxic chemicals and abrasive substances that require special handling and disposal methods.

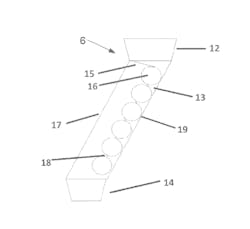

The patent describes a system with a boiler that introduces superheated steam vapor to a holding vessel containing multilayer plastic fragments. The incoming steam heats the vessel to a temperature between 212 and 377 degrees Fahrenheit, raising its interior pressure to between 1 and 12 bar for 10 to 60 seconds. The fragments are then carried to a discharge tank at a relative pressure between −0.7 and 0.1 bar and at a temperature between 59 and 77 degrees Fahrenheit for between 1 and 5 minutes.

The superheated vapor causes heat shock that does not require heating the entire particle to a specified temperature, followed by the mechanical shock from the sudden pressure change to the plastic layers when the fragments are moved to the discharge tank. Together, these forces weaken and break the chemical bonds between the layers.

The multilayer fragments are later transferred to a mechanical separation unit where they are separated into fragments of single-layer plastic. Finally, the fragments progress to a mechanical sorting unit where they are sorted by material.

The time, temperature and pressure of the pressurization and vacuum cycles can be customized to the materials used in the multilayer plastics — for example, polyethylene terephthalate (PET) and polyethylene (PE). However, the method is suitable for separating layers of any other plastic materials. The pressurization and vacuum cycles also can be repeated one or several times depending on the types of plastic and other properties of the multilayer plastic fragments, returning the multilayer plastic fragments through valves and other control means from the discharge tank to the vessel.

The temperature and pressure conditions inside the vessel and the discharge tank remain constant by means of the boiler, valves, pumps or other controls. This prevents energy losses and increases productivity. Steam that enters the discharge tank is extracted through a recovery valve, condensed and filtered, and then the recovered water is reintroduced into the boiler. Since only vapor is heated, rather than the entire mass of plastic fragments, energy is saved and no chemical products are required.

Patent 11858174; published Jan. 2, 2024.

Alpla Werke method protects PET clarity

Alpla Werke Alwin Lehner GmbH & Co. KG of Hard, Austria, received a patent for a method of reclaiming thermoplastic materials for recycling that overcomes the common problem of thermoplastics, particularly polyethylene terephthalate (PET), becoming more yellow, cloudy or gray in appearance over progressive cycles of recycling.

In the method, prepared thermoplastic flakes are exposed to an oxidative fluid and heat, which can range from 320 degrees Fahrenheit to 464 degrees Fahrenheit, for a period of time ranging from 5 minutes to 10 hours.

“The present method according to the invention differs from well-known methods in that ‘contaminating’ reactions are deliberately triggered in order to produce contaminations (yellowing, graying, benzene formation, phenol formation) in order to then separate them in a targeted manner,” the patent states.

Contaminants and agglomerates formed during the process can be taken up by the oxidative fluid and separated from the reaction space. Further separation of solid contaminants can be performed by sifting technologies, and standard sorting systems can be used to remove discolored solid contaminations, or contaminations made brittle and crumbly by the heat and oxidation treatment.

The patent said the process works well when performed following such standard methods as washing the flakes, for example, in alkaline solutions, or cold sorting to separate contaminants such as metal or other plastics.

Agglomerates, adhesives, paints and varnishing or flakes that are stuck or crumbled as a result of exposure to the oxidative fluid are separated by sifting. The patent claims to enable the polymer chain length to be increased to the level of the original raw material.

The patent states that the method works with thermoplastic materials including PET, polylactide (PLA), polyethylene furanoate (PEF), polypropylene furanoate (PPF), high-density polyethylene (HDPE) and polypropylene (PP).

Patent 11794378; published Oct. 24, 2023.

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.