Process to recover polystyrene separates hydrocarbons, solid residues

A patent awarded to Agilyx Corp., Tigard, Ore., describes systems and methods for recycling waste plastics, including P).

Depending on the feedstock and methods used, the feedstock can be converted into a crude oil that can be stored, transported and refined, or it can be converted into a styrene monomer.

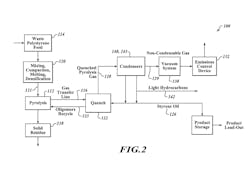

In some embodiments of the invention, the waste feedstock can consist of mixed plastics in ground, chipped or another form; the feedstock might also be primarily PS waste. The plastic waste can be fed into the system in a continuous manner, and the feed apparatus can include conveyors, bins, hoppers and other equipment. The process can include mixing, heating and compacting steps, which can be accomplished with, for example, a compactor and a pre-melter to produce a continuous stream of densified plastic melt. From there, it might flow into a pyrolysis recovery unit (PRU) – or, in other embodiments, the feedstock might feed directly into the PRU.

The PRU can have multiple heating zones, and the heat depolymerizes the feedstock and gasifies or vaporizes a portion of it. Depending upon the embodiment, the feedstock can be heated under atmospheric or vacuum conditions, or with negative or positive pressure. The PRU’s output is then split into separate streams of hydrocarbon gas and solid residues.

According to the patent, “The organic gases can include, for example, one or more paraffins, olefins, naphthenes, aromatics, and/or other classes of hydrocarbon materials. … For example, the vapor can include one or more alcohols, ketones, ethers, phenols, carboxylic acids, or other polar organic molecules.”

From the PRU, the vapor moves to a quenching step, with the quenched pyrolysis gas moving on to a condenser or series of condensers, then on to a condenser. The condenser can separate light hydrocarbons, while remaining vapors pass through a caustic scrubber and an emissions control device before being vented.

In the case of a mainly PS waste feedstock, the vapor stream can be condensed to isolate oligomers. The oligomers can be routed back into the PRU, and the styrene can be condensed, then sent through a supplemental condenser to extract light hydrocarbons.

With a mainly waste PS feedstock, a purified styrene monomer oil product and oligomers can be recovered.

Patent 10,731,080; issued Aug. 4, 2020