Patent Report: Process converts end-of-life plastics into carbon nanotubes

This story appeared in the Winter 2020 edition of Plastics Recycling.

A process that converts end-of-life plastics into carbon nanotubes is the subject of a patent application from Trimtabs Ltd. of Swansea, Wales. The patent application points out disadvantages of conventional methods for turning solid polymers into carbon nanomaterials. It notes that pyrolysis — with or without the use of a catalyst — must be performed at high temperatures, incompletely uses the solid polymers being converted and leaves behind coke or char carbon as waste.

The invention lowers production costs by using unconventional feedstocks instead of precursors derived from petroleum or natural gas. The application notes, “According to the present disclosure, any waste plastic that can be dissolved, dispersed or suspended in a suitable solvent may be utilized as a feedstock.” Raw materials also include biofuels, paints, refrigerants, biopolymers and various other carboncontaining materials.

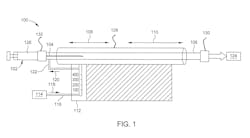

Carbon nanotubes are produced by forming a mixture from carbon-containing material and a metallic catalyst precursor combined with a solvent. This mixture is injected into a carrier gas and conveyed into a reaction vessel that has multiple independent heating zones. The mixture is heated in stages to a maximum temperature of 1,832 F, which facilitates carbon nanotube growth. The carbon nanotubes are then removed from the reaction vessel.

Patent application 20190375639; published Dec. 12, 2019