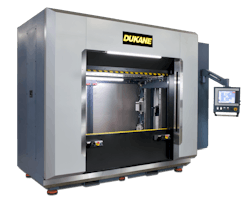

Dukane welders offer control, consistency

LFVW 6970 Machines in this line of low-frequency vibration welders (LFVW) from Dukane have a single-piece construction that includes control cabinet, sound enclosure and frame. They can be used for joining air-bag chutes, automotive ductwork and appliance parts, such as washer drums. Equipped for remote connectivity, the welders have software that can store as many as 200 welding setups. The software allows for real-time graphing of amplitude, force and collapse distance.

What’s new? The welders. With its introduction of the series, Dukane has extended its proprietary technology for controlling the melt of plastic materials to its LFVW offerings. The technology, called Melt-Match, detects the transition of plastic materials from a solid state to a molten state.

Benefits Simplified setup, and better weld quality and consistency. The series’ single-piece design eliminates the disassembling and assembling associated with moving machines between sites and provides for longer machine life. Melt-Match provides precise force sensing, giving users better control of the trigger and weld force and ensuring uniform melt, accurate welds and hermetic seals.

Dukane, St. Charles, Ill., 630-797-4900, www.dukane.com