TwinTool This application from Canadian robotics software provider RoboDK works with the company’s robot programming software to offer fully automated robot tool calibration for industrial robots. Typical calibration methods for finding a robot tool center point (TCP) require users to take readings on at least four joints of the robot arm when moving the tool to the same point in different orientations — a time-consuming manual process that can limit accuracy. TwinTool employs a simpler method of calibrating the TCP to ensure the programming system has an accurate model of the robot's tool. RoboDK’s TwinTool supports more than 600 robot arms from 50 different robot manufacturers and can be used in many industrial environments.

What’s new? The TwinTool application.

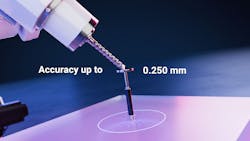

Benefits Quick, easy, cost-effective robot tool calibration. No programming skills are required — a user-friendly wizard ensures the calibration is performed correctly and safely. The only required components are the RoboDK simulation software, a robot, its tool (spherical or conical) and an off-the-shelf linear gauge sensor. Left uncalibrated, robot positioning errors can range from 2mm to 5mm, while calibration can improve accuracy to 0.25mm, the company said.

RoboDK Inc., Montreal, 855-692-7772, www.robodk.com

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.