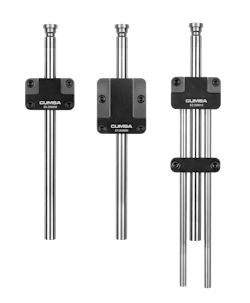

Compact External Ejection System This CUMSA technology can be mounted on the outside of the mold or attached to the plates to give toolmakers a standardized solution for molds that require plate control or sequencing in large molds. Available in several models — the EX, EY and EZ — the technology can control plate sequencing or synchronize ejection. They work with plate movements, such as pre-opening, and can move plates simultaneously, allowing selected plates to stop in a locked position, while other plates continue to move. The EX is designed for a plate pre-opening movement, and it acts as a double ejection system, controlling two sets of ejector plates when the upper ejector plates set are actuated. For use with molds with separated upper ejector plates and lower ejector plates actuated by the machine, the EY also can be applied as a double ejection system. The upper set stops at the core plate, and the rear plate travels until it reaches the upper plate. Meanwhile, the EZ is designed for synchronized mold plates openings. All the systems have available rod diameters of 14mm, 20mm, 32mm and 50mm.

What’s new? A new EB adapter, also called external fixing, that holds the end of the rods when the mold is in action. Users of the EX and EY models need only one adapter at the bottom of the central rod, while users of the EZ system need two adapters — one at the bottom of the central rod and one at the bottom of the lateral rods.

Benefits Ease of installation, smoother movement and the elimination of the need for housings in the plates, when using the EB adapter. The external ejection system has a fully external setup. It is easy to install and can be assembled in two ways, with surface or built-in mounting. The EB gives users a more reliable method of controlling mold plates for big molds, and use of the ejector systems simplifies maintenance. Also, since they only control mold plate openings, the ejection systems do not affect the cycle time, and they never touch the plastic.

CUMSA USA LLC, Troy, Mich., 248-850-8385, www.cumsa.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.