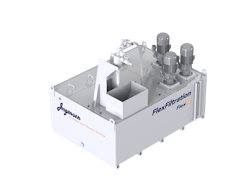

Coolant filtration system Jorgensen Conveyors and Filtration Solutions has expanded its FlexFiltration line of coolant filtration systems that work with CNC machine tools by adding two new versions. The Flex B series uses bag filtration, while the Flex C series incorporates a cylindrical/hydrocyclone filter.

What’s new? The Flex B and Flex C versions.

Benefits Adaptable filtration capabilities. Shops can easily adapt their filtration to meet changing needs for applications involving cast iron, steel, aluminum, composites or plastics, and both versions are available with filters sized to handle flow rates of 30, 60 or 90 gallons per minute. The Flex C introduces contaminated CNC coolant into its cyclonic filter at a high velocity, where the solid contaminants are separated and clean liquid is forced out of an outlet at the top of the filter – so no disposable filter media is necessary. Bag filters make the Flex B a quick, cost-effective method for coolant and cutting fluid filtration for removing small chips, grinding swarf and other particulates. Both versions offer filtration down to 10 microns.

Jorgensen Conveyor and Filtration Solutions, Mequon, Wis., 262-242-3089, www.jorgensenconveyors.com

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.