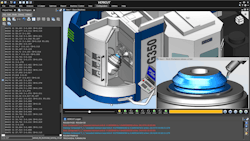

Vericut CGTech’s Vericut software can be used with a wide range of CNC-controlled machines for simulation of machining operations, allowing users to detect errors, prevent potential collisions and optimize processes before the first chip flies on a physical part.

What’s new? Version 9.3, which includes a range of improvements. They include enhancements to the Status window and Heads-up Display (HUD), which each give users the ability to quickly access machine control menus. Users can streamline machining and simulation information, with the ability to control visibility of columns and provide a familiar layout across Vericut sessions by locking or unlocking the visibility of status groups. CGTech displayed Vericut 9.3 at the International Manufacturing Technology Show.

Benefits Improved machining accuracy. The “Pre-Check” function compares data directly from machines to the virtual twin to ensure a match. Users can then rerun a simulation using the updated data to ensure job setup, work offsets and cutting-tool settings are correct and the job will run without problems. User comfort is also enhanced by features like Dark Mode, a display option that eases eye strain by using darker colors.

CGTech, Irvine, Calif., 949-753-1050, www.cgtech.com

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.