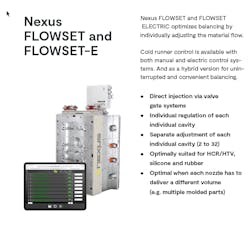

FlowSet This technology from Nexus optimizes the flow of materials like LSR, silicone, rubber and heat-cured rubber in cold runners with between two and 32 cavities. It is ideal for medium to large parts. Both manual and electric control systems are available.

What’s new? Continued improvements of the balancing system and the valve-gate system to reduce friction and wear for longer life, and new remote-access capabilities. At the K Show, injection molding machine maker Wittmann Group exhibited a servo-hydraulic SmartPower 120/350 LIM. It made four different liquid silicone caps for beverage containers using a four-cavity mold from Nexus, equipped with FlowSet needle shut-off regulation.

Benefits The balancing of each individual cavity without interrupting the injection process.

Nexus Elastomer Systems Inc., Chicago, 43-50-1215-200, www.nexus-elastomer.com/en/coldrunner

Wittmann USA Inc., Torrington, Conn.,860-496-9603, www.wittmann-group.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.