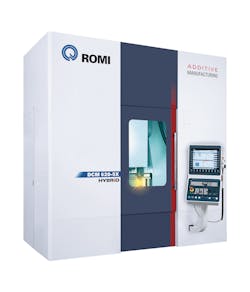

Romi hybrid machine has additive, subtractive capabilities

DCM 620-5X Hybrid This five-axis hybrid vertical machining center from Romi USA combines additive and subtractive metal machining capabilities. It can be used for mold making, mold modification and repair tasks. For example, edges of a mold that will see high wear can be modified by machining down the meeting edges, building up a layer of stronger metal via laser deposition, then finishing the new edge with subtractive machining.

What’s new? Swappable additive heads. A series of heads fits in the automatic tool changer and can be swapped to offer different sizes of laser deposition patterns.

Benefits Time and cost savings. Additive manufacturing can be used more economically to make or modify some parts — for example, where adding material to a workpiece and machining down to a final finish is faster than starting with a larger workpiece and using a long subtractive process to make a finished part. Expensive materials, such as Inconel and stainless steel, can be added in the exact amount required without the waste caused by subtractive machining.

Romi Machine Tools Ltd., Erlanger, Ky., 859-647-7566, www.romiusa.com

Vital statistics | |

X-axis travel | 24 inches |

Y-axis travel | 20 inches |

Z-axis travel | 18.1 inches |

Spindle taper | 40 |

Spindle speed range | 15 to 15,000 RPM |

Maximum workpiece dimensions | 20 inches (diameter) by 13 inches (height) |

Maximum workpiece weight | 660 pounds |