Patent Report: Acro Tool's mesh injection mold speeds cooling

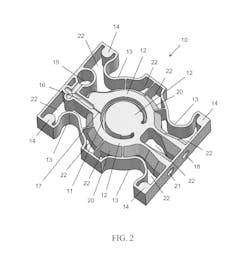

Mesh injection mold. Akron, Ohio-based Acro Tool and Die Co. received a patent for a mold that cools quickly to decrease cycle times.

Inefficient mold cooling increases cycle times for injection molding. Traditionally, molds may incorporate different cooling strategies, including the use of conformal channels near the mold cavity to cool it more quickly by circulating water or another coolant. However, the mold halves still disadvantageously absorb heat and slow cooling due to their solid metal construction.

The mold halves described in the patent contain conformal cooling channels around the mold cavity. However, each mold half’s cooling channel is surrounded by a plurality of through cavities; in a conventional mold those areas would be solid metal. The cavities are filled with a metallic mesh, which reduces the weight of the mold and decreases its required cooling time, while still providing enough strength to support each mold half and withstand clamping pressures. The patent states that the mold halves could be produced using additive manufacturing, and that the thickness of the grid of mesh material and the number of openings in the mesh material could be of a constant size throughout each mold half, or in some embodiments, the mesh material could be of a constant size in one through cavity, and of a different constant size in another through cavity.

“Moreover, if desired, additional cooling could be created by passing cool air through the mesh openings of metallic mesh material,” the patent states.

The quicker cooling time produces shorter cycle times, and thus increased production of parts per hour compared to a conventional mold producing an identical part, according to the patent.

Patent 10,953,582; issued March 23