MakerBot printer now has mold-making applications

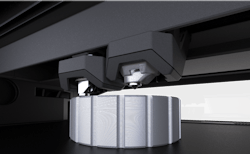

Method This MakerBot 3-D printer has industrial-grade features, including an ultra-rigid steel frame and heated circulating chamber, for printing advanced engineering materials. It features twin extruders that allow users to print support materials, as well as sealed material bays to keep out moisture. To ensure accuracy and facilitate an automated workflow, the printer is equipped with more than 20 sensors, including temperature and calibration sensors, that are in the material bays, chamber and extruder.

What’s new? Compatibility with BASF's Ultrafuse 316L stainless steel, which augments a material portfolio that already includes a stable of plastics, such as composite materials, polylactic acid, PET-glycol, ABS and nylon. A polymer binder is used in the process, and removed after printing by debinding and sintering.

Benefits The ability to make metal mold components, tooling, jigs and fixtures.

MakerBot Industries LLC, Brooklyn, N.Y., 347-334-6800, www.makerbot.com

Vital Statistics

| Length | 1.4 feet |

| Width | 1.4 feet |

| Height | 2.1 feet |