Altair brings simulation to injection molding

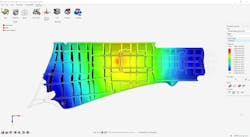

Inspire Mold Altair, which has simulation-driven design software for casting, extrusion and additive manufacturing, turns to injection molding with its Inspire Mold simulation software. It has an intuitive five-step workflow that designers and engineers can use to design molds that minimize shrinkage, warpage, sink marks and weld lines.

What’s new? Inspire Mold.

Benefits Fast simulation. Inspire Mold uses a next-generation 3-D technology to perform its simulations without requiring specialized computing hardware. This allows for quicker design iterations to optimize the quality and manufacturability of parts, without building and reworking prototype molds, avoiding the time and cost those require. Data for 60 polymers is embedded in the software, and users with a license for the Altair Material Data Center will soon have access to all of that material data.

Altair Engineering Inc., Troy, Mich., 248-614-2400, www.altair.com