What was “cool” in the 1990s might be described as “fire” in the 2020s.

Language changes, but, with a common starting point, navigating the jargon becomes easier.

That’s the goal of efforts to refresh “Customs and Practices of the Moldmaking Industry,” a 21-page Plastics Industry Association document, which, since the 1980s, has provided both mold builders and mold buyers with a framework for talking about expectations. Last updated in 1996, the guide provides mold data sheets, and lays out practices for making payments, receiving progress reports and arranging mold delivery.

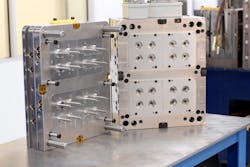

It also establishes levels of mold quality, so that whether the mold is for a medical part or a truck bumper, mold makers and their customers share a common language.

Glenn Starkey, the president of Wauconda, Ill.-based Progressive Components, is heading up the four-person task force responsible for initial edits of the guide. He said the classifications have proved valuable.

“Buying a mold is different than placing an order for 1,000 sprockets. It’s a quantity of one, and it’s got a whole lot of details and variables to it, so any assistance as to what the traditional rules of the road are helps things go smoothly from a business standpoint,” he said.

“The terminology that has existed within this guide became the vernacular throughout the '80s and '90s and still till this day, so you’ll frequently hear a mold maker, be it in the U.S. or outside the U.S., refer to the ability to build a Class 101 mold.”

The mold classifications, based on characteristics such as expected number of cycles and substrate hardness, have held up well over time, but Starkey said other aspects of the guide are showing their age.

For example, terms like numerical-control tape, mylars, hobs and mandrels might sound foreign to the ears of younger mold makers.

“Somebody in the mold business might get a chuckle remembering some of these terms from 30 years ago,” Starkey said. “There are also references to forms and how pink carbon copies are filed for internal use. We will update that to an electronic form.”

In addition, the task force, which includes Toby Bral of MSI Mold Builders in Cedar Rapids, Iowa, and Wally and Camille Sackett of Accede Mold & Tool in Rochester, N.Y., is reviewing practices for mold payments, mold qualification and warrantying mold performance. The members plan to update the mold data sheet, which is used for producing project quotations, as well as the progress report template that provides information about mold status during the build process.

The group has been meeting since September, and Starkey said it will begin soliciting input from others sometime in early 2021. To provide input, interested mold buyers or makers can email him at [email protected].

Karen Hanna, associate editor

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.