New formulation makes sturdier silicone molds

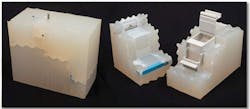

SES22251 This silicone from Shin-Etsu Silicones of America Inc. is ideal for creating hand-cast molds for rapid prototyping of plastic parts. A box or container is built to hold the master part, which can be a 3-D printed part, then the silicone is added and cured. The mold is then cut to remove the master part, and the mold can be filled with the desired material, including urethane or acrylic. The base silicone can be mixed with one of four catalyst options to achieve the desired hardness.

What’s new? The formulation, which the company completely redesigned.

Benefits Molds that are less expensive than metal, and more durable than some other silicone variants. This formulation offers higher tear strength, which means a longer working life for molds made with it, and the ability to produce more parts from a single mold. It also makes creating molds for prototyping quicker and easier, because its low viscosity means it flows better and reduces the chance for unwanted bubbles, while its translucent color makes it easy to see the master part and cut the mold around it.

Shin-Etsu Silicones of America Inc., Akron, Ohio, 800-544-1745, www.shinetsusilicones.com