StackTeck is responding to unprecedented market demands for high-volume injection molds for medical applications.

“Never before have we seen such a wave of inquiries for high-volume medical applications,” said Jordan Robertson, VP of businessStackTeck offers molds for medical-disposable items, labware, testing and diagnostic plastic components. Many of these components are intricate and require complex mold ejection sequences and/or designs, and quality optical finishes, he said.

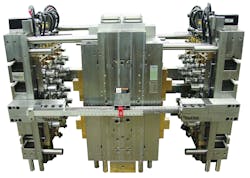

Stack mold technology allows the company to create the right medical product in combination with other technologies that are part of StackTeck’s offerings, including multi-material, collapsing core, servo unscrewing, quick product change and in-mold functions such as in-mold closing for flip-top closures.

High-volume molding technology is proving to be the most efficient and cost-effective way to reach high levels of productivity using:

- Advanced cooling designs for optimal cycle times;

- Specialty hot runners for tight pitches to maximize cavitation; and

- Stack molds to increase productivity of each injection molding machine.

Stack mold designs have evolved to fill the needs of a wide variety of injection molding medical applications. The features and capabilities of stack mold technology are well-suited for the high production volumes required today, Robertson said.

Contact:

StackTeck Systems Ltd., Brampton, Ontario, 888-700-8555, https://stackteck.com/