Affordable, all-electric, user-friendly: Injection molding machines at K 2025

Key Highlights

- All-electric injection molding machines were a major focus at K 2025, driven by high energy costs and stricter environmental regulations, especially in Europe.

- Manufacturers like Dr. Boy, Arburg, and KraussMaffei introduced new electric and hybrid models with advanced control systems, shorter cycle times and compact footprints for diverse applications.

- The packaging industry is a primary focus, with over a dozen new machines designed to meet EU recycling mandates and support sustainable packaging solutions.

- AI and IoT integration, such as KraussMaffei’s CFP technology and Fanuc’s Roboshot Linki2, are enhancing process monitoring, energy efficiency and predictive maintenance.

- Control systems improve cybersecurity, simplify operation and facilitate remote machine management, aligning with Industry 4.0 trends.

By Ron Shinn

The trends for injection molding machines (IMMs) displayed at K 2025 in Düsseldorf, Germany, were easy to spot — all-electric, lower-cost alternatives, labor savings and packaging.

There were hydraulic and hybrid machines on display, but the noticeable majority of new machines were electric. You can thank high energy costs and environmental regulations, particularly in Europe over the past five years, for driving this trend.

At the same time, processors have embraced the precision and efficiency of all-electric presses.

Dr. Boy, for example, introduced its first-ever line of all-electric presses and expect they will become popular with processors. “We have them in the showroom now and are ready to take orders,” said a Boy spokesman.

There were also plenty of lower-cost IMMs displayed or discussed. Machinery makers refer to these as standard machines, with fewer options and less customization possible.

Arburg made a splash with its new all-electric Trend line, which consists of four models. The company positioned the line as featuring low initial investment, low operating cost, easy to operate and providing a fast return on investment.

Engel added a machine to its low-cost Wintec line, which has been successful since its introduction 11 years ago; the Wittmann Group introduced a standard press; and a Sumitomo (SHI) Demag official said his company is currently “investigating” a standard machine.

Without exception, machinery makers described their machine design and latest control systems as being easy to learn and operate. There were different levels of adoption of artificial intelligence (AI) in control systems, but even companies not pushing AI said their systems could help processors reduce labor costs.

Also worth noting — KraussMaffei said its new MC7 control system offers increased protection against cyberattacks.

The end market that seems to be getting the most attention is packaging. More than a dozen new machines are aimed at packaging.

Engel Group CEO Stefan Engleder described the plastics processing machinery industry as being in a “structural crisis,” but he said “packaging technology is a challenging market, but the demand for standard applications and solutions with recycled materials remains stable.”

He added that the European Union’s Packaging and Packaging Waste Regulation, which will be mandatory next August, is adding momentum for new solutions. The regulation requires all packaging in the EU be recyclable by 2030 and bans some single-use plastics.

Here are some of the machinery highlights:

Dr. Boy unveils first all-electric presses

Dr. Boy went big by introducing an entirely new line of small IMMs, its first all-electric molding machines.

The four machines in the series range from the Boy 35 Electric, with about 39 tons of clamping force, to the Boy 100 Electric, with about 102 tons of clamping force. There is also a 55-ton and an 88-ton model.

All have electromechanical drives for injection, dosing and ejection. Dr. Boy said the new series has outstanding dynamics, precise position detection and shorter cycle times.

The injection unit has been redesigned and features patented back pressure measurement. Dr. Boy developed a dynamic pressure measurement system that monitors the force transmitted to the screw with a force sensor, then sends data to the control system to be analyzed.

The presses have a two-platen clamping unit that is free of oil and lubricants in the molding area.

The electromechanical ejector delivers precise movement without stick-slip, both at full loads and slower operations.

The Boy 35 Electric has a 280mm-by-254mm distance between the tie bars. The Boy 100 Electric has a 430mm-by-360mm distance. A trip chute is accessible from three sides to make part removal easier.

The new series uses Dr. Boy’s Procan Alpha 6 control.

All four machines have a small footprint. The Boy 35 Electric has a footprint of less than 24 square feet. The largest in the series, the Boy 100 Electric, has a footprint of just 43 square feet.

A Boy 50 Electric was running at K 2025 with an LR 5 linear robot fully integrated into the molding machine’s control system. This lets the robot act as an integral part of the molding machine. Benefits include an automatic link between the data sets of the robot and press, a common alarm system and event logging that simplifies fault diagnosis.

Arburg sees Trend for low-cost IMMs

Arburg managing partner Michael Hehl described his company’s new Allrounder Trend IMM series as a strategic expansion of its portfolio.

“With the new machine concept for standard applications, we are offering a new standard machine — and are thus also addressing an extended customer base,” Hehl told a press conference.

Arburg’s reputation is for building precision, specialized machines. But the company's new lower-cost electric Trend series is designed for standard applications. Delivery is promised in four weeks. There are four sizes in the Trend series, with clamping forces ranging from 56 to 225 tons of clamping force.

The company said the line includes a clearly defined list of available equipment. The Trend machines have a small footprint and are simple to set up, operate and maintain.

“They offer cost efficiency and proven Arburg quality,” said Guido Frohnhaus, managing director of technology. “The low investment and operating costs, combined with a fast return on investment, also make these machines interesting for new markets where cost pressure prevails.”

The Trend series has a Gestica Lite controller, which Frohnhaus described as a variant of Arburg’s high-end Gestica control system.

The line will replace Arburg’s Allrounder Golden Electric series.

Arburg achieved the Trend’s lower price in part by redesigning the clamping unit and developing a new system for modularity. Frohnhaus declined to say how much less the Trend machines will cost or where they will be manufactured. He did say the Trend machine price will be competitive with Arburg’s Asian competitors.

Injection speeds range from 200mm per second on the Allrounder e 500 Trend to 500mm per second on the Allrounder e 1000 Trend.

Distance between the tie bars goes from 370mm on the e 500 Trend to 570mm on the e 1800 Trend. Platen daylight ranges from 500-750mm on the e 500 Trend to 700-1,100mm on the e 1800 Trend.

Arburg also showed a new vertical model, the Allrounder 475 V, designed for products in the e-mobility, electronics and medical markets.

The 475 V has a small footprint with a large mold installation area. The company said it uses 60 percent less energy, thanks to servo hydraulics, and is competitively priced.

The 475 V has a clamping force of 112 tons. Arburg sells four other vertical presses, ranging from 28 tons of clamping force to 225 tons.

It can be used for both manual and automated insert molding.

Shibaura shows electric, hydraulic IMMs

Shibaura Machine launched two new IMMs, the all-electric EC75SXIII and the hydraulic S-GenXt 180-7A.

The electric EC75SXIII, with 75 tons of clamping force, is the latest addition to a line that includes clamping forces ranging from 33 tons to 3,306 tons. Shibaura said the line is suitable for medical, packaging, automotive, aerospace and other products.

The new press features linear guides on the moving platen for rigid, precise movements, grease-free tie bars, a five-point Linkline toggle mechanism that is angled to distribute force evenly across the platen and a strain gauge on the tie bar to monitor actual tonnage. Distance between the tie bars is 410mm by 360mm.

The EC75SXIII comes with Shibaura’s V70 control system, which has a 19-inch, split-screen monitor with drag and drop capabilities. The V70 also has on-screen help functions for inexperienced operators who need to set up a new tool or diagnose and correct common molding problems.

The hydraulic S-GenXt 180-7A has 180 tons of clamping force. It is aimed at the packaging market.

It features high-speed pressure accumulators and reduced energy consumption.

The S-GenXt is also equipped with Shibaura’s Virtual Machine Expert, an AI-powered monitoring system that continuously analyzes machine performance and alerts operators of potential problems.

Shibaura is based in Japan. The SXIII molding machines are built in Japan, while the S-GenXt presses and auxiliary equipment are built in India.

KraussMaffei relaunches workhorse PX line

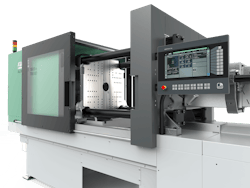

KraussMaffei relaunched its all-electric PX series of IMMs, describing it as “the most modern all-electric injection molding machine in the world.”

Jörg Stech, chairman of the management board and CEO of KraussMaffei, said, “We have made it more compact, more productive and more sustainable from the ground up.”

Stech said it’s 25 percent more energy-efficient than previous PX machines. The footprint is 23 percent smaller, and a new control system is simpler and more intuitive. He said the series has a high overall equipment effectiveness (OEE).

The new PX series is being relaunched with clamping forces ranging from 90 tons to 225 tons. The original PX series machines were introduced nine years ago.

Stech said the series features a new structural design with optimized arrangement of individual components, new servo drive technology with electric ejector, and a modular, space-saving enclosure.

Like previous models, the new series retains large tie-bar spacing to accommodate complex and heavy molds, wider support of the moveable clamping plate for plate parallelism, and linear guide for efficient movement.

Main axes and the ejector are servo-electric for improved performance and energy reduction. An optional compact, servo-hydraulic auxiliary unit is available.

Mold cooling and temperature controls, as well as hot-runner controls, have been optimized.

The new MC7 control system is web-based with intuitive operation, according to Stech. It eases setup, operation and maintenance and increases everyday production efficiency, he added.

The MC7 meets the future requirements of the European Union’s Cyber Resilience Act (CRA), which provides increased protection against cyberattacks.

In addition to the redesigned PX series, KraussMaffei demonstrated new chopped fiber processing (CFP) technology, which enables direct, fiber-friendly compounding of PP and chopped glass fibers in the injection molding process for the first time.

“With the unique CFP technology, we offer our customers a true game-changer that significantly reduces their material costs in the production of fiber-reinforced components.

“We are particularly proud of the heart of the new CFP technology, the patented screw geometry, which was developed specifically for the technology by KraussMaffei,” Stech said.

The new technology is different in that instead of using pre-compounded long glass-fiber granulate, separate dosing of PP and glass fiber is possible. Stech said both components can be fed with the molding machine’s conveyor system, homogenized in the cylinder and gently processed by the new CFP screw.

This processing system eliminates fiber clusters that can occur during processing, so material costs are lower.

The company said the technology allows processors to individually dose and mix polymers and fibers to develop their own formulas, which can be a competitive advantage.

The system is retrofittable on KraussMaffei molding machines, and an ROI of one year is possible.

The CFP process is expected to have a wide range of applications, particularly in automotive, aerospace and technical consumer products.

Engel fills a gap with Victory Electric

Engel has extended the Victory Electric molding machine series with the 220 model, the largest and most powerful of the six-press line, and added a new Wintec E-win 1800 to its lower-cost line. It showed both for the first time.

The Victory Electric 220 has 247 tons of clamping force. It has a redesigned clamping unit and Engel’s well-known tie-bar-less technology, along with electric drive systems. It is designed for high-volume, precision parts, according to the company.

Engel said the Victory Electric 220 fills a gap in the market for processors that want a tie-bar-less press with electric technology and higher clamping force.

The new clamping unit has two vertical pressure bars to replace the traditional toggle mechanism. An independent deformation-compensation system maintains platen parallelism and stability.

A servo motor with ball screw powers all main movements electrically. A recovery system for braking energy reduces overall energy consumption and improves the carbon footprint of the process.

The Victory Electric 220 has plenty of space for core pulls because of its large platen area and spacious, unobstructed mold area. A standard integrated hydraulic unit enables the use of hydraulic core pulls.

The press is equipped with a 650mm-wide drop-out chute.

Screw diameters ranging from 25mm to 70mm can be used, depending on the injection unit.

Engel’s new all-electric Wintec E-win 1800 high precision IMM with a compact design and lower cost is aimed at processors that need standard machines on short notice.

The Austrian manufacturer said it is specifically designed for the small and medium-sized machine market.

Two electric ball screws combined with a belt drive power nozzle movement. This design provides fast injection and high repeatability, according to Engel. A swiveling injection unit permits fast screw changes.

A five-point toggle lever mechanism allows large opening strokes and automatically adjusts the mold installation height. A reinforced frame on the moving platen minimizes deformation and optimizes force distribution.

The ejector also operates on a servo drive with two ball screws.

The press uses Engel’s C3 control system, which has the same user interface as Engel’s CC300 controller.

The E-win 1800 is compatible with Engel’s various digital assistant systems.

It is being rolled out globally, but an Engel spokesman could not give an exact date when it will be available in North America.

Engel has sold more than 1,500 Wintec machines since the brand was introduced 11 years ago. Engel manufactures them in China.

Wittmann MacroPower injection unit pivots

Wittmann Group has redesigned the MacroPower servo hydraulic IMM by adding a pivoting injection unit for faster screw changes, a Unilog B8X control system and a compact, one-piece machine body.

The updated design will be available on smaller MacroPower presses from 440 tons to 661 tons of clamping force. The entire MacroPower line ranges from 440 tons to 2,425 tons of clamping force.

A second new press, the all-electric EcoPrimus, also made its debut. The EcoPrimus is in the standardized category aimed at mainstream applications needing fewer options.

The EcoPrimus demonstrated had 110 tons of clamping 1orce.

Wittmann said the EcoPrimus 100 is available for quick delivery and offers especially good price-to-performance ratio. It also carries Wittmann’s latest Unilog B8X control system. Significant energy savings are possible, the company said.

The MacroPower press shown had 551 tons of clamping force. The freely accessible, swiveling injection system, which is accessible from the front and rear of the machine to make screw changes easier, is a unique feature for the new design. It offers lateral mold insertion through virtually tie-bar-less access.

The MacroPower also has a patented swivel locking system, an air-cooling system for drive and amplifier units, and a high-resolution position measuring system for closing movements.

An energy-recovery system is standard.

The MacroPower line’s linear guide system on the moving platen ensures fast energy-saving movement, a clean mold space and maximum precision in mold protection, according to the company.

The molding machine also comes with Wittmann’s Drive-on-Demand technology, which reduces energy consumption by up to 40 percent. The system eliminates idle current demands, and cooling costs are reduced. No oil cooling is required during normal operations.

Sumitomo highlights multicomponent press

Sumitomo (SHI) Demag, which announced in September it would phase out production of hydraulic presses in Europe, displayed eight all-electric IMMs at K 2025, highlighted by a new 2K IntElect 350t multicomponent press.

The press includes a top-entry SAM-C20 robot and a secondary injection unit situated at a 45-degree angle above the main unit.

By shifting focus to all-electric machines worldwide, Sumitomo (SHI) Demag is moving to more specialized solutions for processors. It will continue to build a smaller number of hydraulic machines in China.

The IntElect 350t includes such special features as a large tie-bar distance for maximum turning diameters, perfectly aligned injection axis drives for higher precision and low energy consumption. These designs provide short cycle times.

The company’s fully automatic activeMeltControl (aMC) system is standard. It compensates for shot-weight variations. Shot-weight variations in 100 percent recycled material can be corrected by aMC to run at the same level as virgin resin.

The new press also includes activeAdjust, Sumitomo’s unique process optimization system that allows the operator to select the best machine control characteristics with slide controls. This means the molding machine can be easily adjusted for a specific product to achieve the shortest possible cycle time.

The NC5+ control system has adjustable clamp force stages, automatic production documentation, automatic mold height and clamping force adjustments and an automatic injection system for faster shutdown and startup.

Sumitomo (SHI) Demag said the press can perform sandwich molding, foaming and fiber-glass multicomponent molding.

The IntElect multi can be supplied with an integrated turntable that can position the cavities between the first and second shift in just 1 second.

Sumitomo (SHI) Demag builds the included SAM-C20 robot, which is integrated into the molding machine’s control system.

Haitian’s new IMMs are for packaging

Haitian showed two new-generation IMMs for the first time, the high-speed electric Zhafir Zeres F and the servo-hydraulic Mars F Pro. Both are for packaging applications.

The Zeres F has 230 tons of clamping force and an 830 injection unit. Injection speed is up to 500mm per second with high process stability.

AI-supported intelligent mold protection with real-time monitoring is included. The system detects deviations of 0.01mm in less than 0.05 second.

A new cylinder heating technology reduces energy consumption by up to 30 percent.

At the trade show, the fifth-generation Zeres F was running 500 milliliter (ml) thin-wall PP food containers with an integrated in-mold-labeling (IML) system in a four-cavity mold with a 3.2-second cycle time. Haitian developed the IML in-house.

The Mars F Pro has 380 tons of clamping force and a 2.33 injection unit. Injection speed is up to 800mm per second. The plasticizing unit is servo-driven.

The machine has a servo-hydraulic drive with infrared heating for higher energy efficiency. It also features RFID-based access, intelligent diagnostics and integrated lubricant management.

Haitian said it is optimized for thin-wall, high-cavity molds with fast, stable cycles and for seamless automation integration.

At the show, a Mars F Pro was molding a 2-liter round PP container in a two-cavity mold with a shot weight of 1.3 grams. Cycle time was 5 seconds.

Haitian, the world’s biggest builder of injection molding machines with 53,000 presses delivered in 2024, also introduced two versions of HT-Xtend, its AI tool for setting up, optimizing and monitoring the molding process. It comes in Lite and Advanced versions.

The system automatically compensates for product weight variations; monitors and manages energy use; optimizes charging and cuts velocity as needed; adjusts oil based on cycle times and pressure; automatically compensates in real time for injection process faults; and supports multi-stage pressure molding.

Fanuc Roboshots offer faster cycle times

Fanuc’s newest IMMs are the all-electric Roboshot S180C and Roboshot S350C — so named for their clamping forces in metric tons. The tonnages equate to around 200 and 385 short tons.

With no need for oil, or oil filtration and disposal, the Roboshots are ideal for clean rooms.

According to Fanuc, the compact machines boast precision, enhanced productivity and high-speed motion. They have fast mold close/open speeds for faster cycle times and greater throughput.

For more clamping force, greater opening stroke, wider tie-bar spacing and increased installation height, the new Roboshots feature an advanced, redesigned clamping unit and increased clamping stroke, and they can accommodate larger molds than conventional presses.

With tie-bar dimensions of 560mm wide by 560mm high, the Roboshot S180C has tie-bar spacing height that’s 50mm bigger than a previous Fanuc model; the dimensions are 830mm by 830mm for the Roboshot S350C, which has 120mm more tie-bar spacing height than a previous model. The Roboshot S180C has a mold/open closing stroke of 450mm, while the bigger machine has a mold/open closing stroke of 730mm; both stroke measurements are bigger than previous models.

Offering a reduction in open/close time of almost 1 second compared with the previous model, the Roboshot S350C is ideal for packaging.

According to Fanuc, the Roboshots’ pre-injection function can reduce cycle times by 0.3 second to 0.7 second.

The machines are designed to reduce energy consumption by 50 to 80 percent while maintaining repeatable and precise cycles that are 5 percent to 50 percent faster than hydraulic machines.

Smarter process controls and AI-powered, real-time energy monitoring result in reduced energy consumption, supporting sustainability efforts.

AI systems can alert the operator before problems occur and provide more effective maintenance, and allow for fewer repairs, less downtime and less risk of human error.

Also, a new plasticizing energy monitor contributes to savings through better energy balance, and an eco-temperature adjustment function further supports reduced energy use.

At the show, Fanuc also showed off its Roboshot-Linki2, an IoT solution that enables remote monitoring and visualization of data from up to 1,000 Roboshot machines via smartphone, tablet or PC.

For the latest Roboshot series, data can be shown directly on the machine using split screen. Linki2 can shorten response time in case of issues, automatically detect molding process abnormalities and improve efficiency.

With the IoT solution, users can remotely monitor their machines and can interface with Enterprise Resource Planning (ERP) software systems using Euromap communications.

In the U.S., Fanuc offers its presses exclusively through a partnership with Milacron.

Stork’s press designed for thin-wall packaging

Stork Plastics Machinery is never shy about describing its IMMs.

At the K show three years ago, a sign on one of the company’s presses claimed it was the world’s most energy-efficient hybrid. This year, a Stork official described the company’s new, all-electric 6600-3550 with 2K (two-component molding) as the highlight of the whole K show.

The new IMM offers high performance for thin-wall packaging products.

The key innovation enabling fast electric injection is a pair of low-inertia, electric motors driving a rack-and-pinion drive. This makes fast acceleration and deceleration possible.

Stork launched its first all-electric IMM line in March 2025. Clamping forces range from 254 tons to 1,121 tons. The newest machine in the line has a clamping force of 662 tons. The all-electric line is designed for flower pots, pails, food packaging and other thin-walled products, the company said.

Stork said the combination of heavy-duty performance with all-electric precision makes the 6600-3550 unlike anything currently on the market. In addition to the mold filling performance provided by fast injection acceleration, it achieves exceptional flow length- over-wall thickness ratios.

The machine has an improved platen stiffness, linear guides under the moving platen, and clamped toggle pins. Stork said the noise level has also been substantially reduced.

At K 2025, a 6600-3550 press produced a two-cavity, 5-liter PP pail with a handle and in-mold decoration in 5.9 seconds.

Injection speed is 450mm per second. Dry cycle time is 2.1 seconds. The screw is 72mm.

Stork stressed that the machine is designed to provide protection for the mold and reliably run 24/7 at short cycle times with low energy consumption.

The control system is Stork Injection Control (STIC). It is capable of correcting for material variations in real time. This is particularly useful when processing recycled material, the company said.

Stork is based in the Netherlands.

Tederic’s new hybrid combines speed, performance

Chinese manufacturer Tederic Machinery unveiled its new Innova 250 high-speed hybrid IMM designed for the packaging industry.

A joint Chinese and German team spent four years developing the new series, according to Daniel Ammer, VP for research and development at Plastivation Machinery GmbH in Munich, a mechanical engineering company that is Tederic’s partner in Europe.

“With its electro-hydraulic hybrid drive, Innova offers substantial advantages, especially for packaging applications, and ensures efficient production and significantly reduces energy consumption,” Ammer said when he introduced the new press. “Its robust mechanics ensure high performance and extend the service life of the machine and tools.

“I think this is the perfect combination of speed and performance.”

Ammer also said the series features an efficient plasticizing system and a new screw design to ensure high throughput and homogeneous melt.

The accumulator-assisted, closed-loop injection system has a speed of 700mm per second. At K 2025, the machine, with 250 tons of clamping force, was producing HDPE bottle caps weighing 1.25 grams in a 24-cavity mold with a 2.9-second cycle time.

The toggle-style clamping and plasticizing units are electric, and an energy-recovery braking system is standard. The toggle has a closed-loop lubrication system.

Space between the tie bars is 650mm by 650mm. Maximum daylight is 1,320mm. Screw diameter is 50mm.

Ammer said the control interface is designed to be user-friendly. Keba built the controller.

Tederic has not yet announced other press specific sizes it plans to offer, but Ammer said the Innova series would go up to 650 tons of clamping force.

Nissei micromolder has upgraded control

Nissei has a new micro molding press for the North American market, the all-electric NEX30V-1EN1, which features a two-stage, high-precision injection unit that consists of a screw and plunger.

The NEX30V, which it showed for the first time, has 33 tons of clamping force.

The addition of Nissei’s new Tact5 controller is an upgrade from the previous model. The Tact5 system includes Industry 4.0 capabilities.

The micro molding press has a 14mm screw diameter. Clamping stroke is 230mm and ejector stroke is 50mm.

Maximum daylight opening is 605mm. Tie-bar clearance is 310mm by 310mm.

Nissei demonstrated the machine molding battery seal caps. The demonstration featured N-constellation, Nissei’s trademarked IoT package that allows the IMM to serve as a network hub, integrating auxiliary equipment and connecting into a smart factory.

Senior staff reporter Karen Hanna contributed to this report.

Contact

Arburg Inc., Rocky Hill, Conn., 860-667-6500, www.arburg.com/en/us

Boy Machines, Exton, Pa., 610-363-9121, www.boymachines.com

Engel Machinery Inc., York, Pa., 717-764-6818, www.engelglobal.com

Fanuc, represented by Milacron, Batavia, Ohio, 513-536-2000, www.milacron.com

Haitian, represented by Absolute Haitian Corp., Worcester, Mass., 508-459-5372, www.absolutehaitian.com

KraussMaffei Corp., Florence, Ky., 859-283-0200, www.kraussmaffei.com

Nissei America Inc., San Antonio, 714-693-3000, https://nisseiamerica.com

Shibaura Machine Co. America, Elk Grove Village, Ill., 888-593-1616, www.shibaura-machine.com

Stork IMM USA LLC, Swedesboro, N.J., 215-987-9665, www.storkimm.com

Sumitomo (SHI) Demag, Suwanee, Ga., 678-892-7900, https://sumitomo-shi-demag.us

Tederic North American Machinery Inc., Palmetto, Fla., 941-323-9081, www.tederic-na.com

Wittmann USA Inc., Torrington, Conn., 860-496-9603, www.wittmann-group.com

About the Author

Ron Shinn

Editor

Editor Ron Shinn is a co-founder of Plastics Machinery & Manufacturing and has been covering the plastics industry for more than 35 years. He leads the editorial team, directs coverage and sets the editorial calendar. He also writes features, including the Talking Points column and On the Factory Floor, and covers recycling and sustainability for PMM and Plastics Recycling.