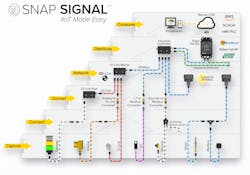

Snap Signal Banner Engineering produces a variety of industrial products including sensors, machine safety and connectivity technologies. Its Snap Signal product line combines software and modular hardware that can be attached to the components of nearly any machine, including injection molding machines, to capture data and convert it to a common protocol to provide Industrial Internet of Things (IIoT) insights. Snap Signal’s splitter connections are attached to existing devices such as sensors, motor controllers and lights in an overlay network that collects data without disturbing the existing control infrastructure. The hardware includes signal converters, wireless networking, IO-Link masters and hubs, and an industrial controller. Collected data can be sent to a cloud dashboard or a supervisory control and data acquisition system.

What’s new? The Snap Signal system.

Benefits Industry 4.0 functionality for legacy systems. Snap Signal is easily scalable, so users can start as small as monitoring a single sensing point and use that data as a pilot to assess the potential future return on investment. The system is quick and easy to deploy. Users who don’t already have a cloud dashboard of their own can choose to use Banner Cloud Data Services.

Banner Engineering Corp., Minneapolis, 888-373-6767, www.bannerengineering.com

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.