By Karen Hanna

A new optional drive for Boy’s eSP injection units features a second servomotor pump that allows it to drive machine movements simultaneously.

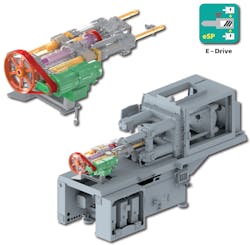

The new drive, called the E-Drive, which is available in international Size SP170, features two servomotors that provide electromechanical injection and metering movements. According to Boy Machines President Marko Koorneef, the setup is appropriate for dealing with applications that require relatively larger volumes of material or longer cycle times.

“With the optional eSP, you can open the clamp and at the same time do a screw recovery, saving cycle time and/or metering high quantities and keeping the cycle time as short as possible,” he said.

The optional drive and injection units are compatible with four machines: Boy 60 E, Boy 80 E, Boy 100 E and Boy 125 E, with clamping forces ranging from about 66 tons to about 138 tons. When ordered with the E-Drive injection unit, the presses’ model names are followed by the designation of “hybrid.”

Koorneef said, unlike the optional drive, the standard drive is hydraulic and has only one pump. It cannot support simultaneous movements.

The components, including spindle, bearing, motors and converters, of the E-Drive plasticizing unit feature high-quality cast construction. To ensure precision and repeatability, the E-Drive has an extremely rigid injection axis. Accuracy in maintaining the switching-points of the set injection process is guaranteed within a tolerance of 0.01mm.

In addition to introducing the E-Drive over the summer, Boy has been rolling out upgraded, more compact presses. For example, with a clamping force of about 110 tons, the Boy 100 E hybrid injection molding machine features a reduced machine length of about 11.5 feet — about 1.1 feet shorter than earlier models. In all, its footprint measures about 52 square feet.

As standard, all the presses have two servo pumps, and all motions of the injection molding process, including the ejector, core pull, metering, mold and injection movements, can be controlled simultaneously via four independent servomotor drive axes.

Karen Hanna, associate editor

Contact:

Boy Machines Inc., Exton, Pa., 610- 363- 9121, www.boymachines.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.