PMM's top 10 most-read stories of September

The most-read stories published in September on PlasticsMachineryMagazine.com included an in-depth look at processors who specialize in molding tiny parts such as medical devices and electronics components; an interview with industry veteran Stan Glover; stories from our report on machinery for sustainable materials; and tips for preparing your plastics business for severe weather and related emergencies. Did you miss any?

1. In-house mold making, custom solutions and dedication to precision are among the factors that help micromolders succeed in creating parts so tiny that tolerances are measured in microns. https://www.plasticsmachinerymagazine.com/injection-molding/article/21152936/micromolders-find-their-fit

2. Machinery manufacturer Milacron offered ideas for expanding your machinery utilization and production through aftermarket upgrades of existing assets.https://www.plasticsmachinerymagazine.com/injection-molding/article/21152838/the-economics-of-increasing-injection-molding-capacity-through-aftermarket-upgrades

3. In addition to his work at Zeiger Industries, Stan Glover is a leading voice in standardizing safety requirements and practices for processing machinery around the world. https://www.plasticsmachinerymagazine.com/injection-molding/article/21151943/stan-glover-sets-high-standards

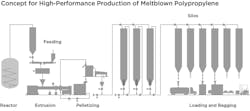

4. Coperion has validated its ZSK twin-screw extruders for producing PP pellets that are tailored for the melt-blown fabrics used to make masks for medical personnel. https://www.plasticsmachinerymagazine.com/extrusion/article/21150417/coperion-extruders-can-compound-pp-for-meltblown-mask-material

5. Sentry Insurance a Mutual Company advises carefully assessing — and practicing — your plans to keep your employees safe in the event of a weather emergency. https://www.plasticsmachinerymagazine.com/injection-molding/article/21153932/how-to-prepare-your-plastics-business-for-severe-weather

6. Extruder OEMs are reporting increased demand for extrusion systems tailored for recycled plastics and bioplastics. https://www.plasticsmachinerymagazine.com/extrusion/article/21148500/interest-grows-in-extruders-designed-for-recycled-plastics-and-bioplastics

7. Davis-Standard has seen increased sales of extruders for recycling during the past two years, and growing interest in bioplastics for producing alternatives to banned items such as plastic straws, said John P. Christiano, VP of technology. https://www.plasticsmachinerymagazine.com/recycling/article/21149281/davisstandard-sees-bump-in-extruder-sales-due-to-recycling

8. Mold maker StackTeck and auxiliary equipment manufacturer Advanced Extruder Technologies discuss modifications they must make to handle sustainable resins. https://www.plasticsmachinerymagazine.com/extrusion/article/21148523/mold-makers-auxiliary-equipment-manufacturers-help-process-recycled-materials

9. Processors aren’t on their own when they decide to tackle tricky new bioplastics or recycled resins; increasingly, injection molding machinery OEMs have their backs. https://www.plasticsmachinerymagazine.com/injection-molding/article/21148463/arburg-wittmann-battenfeld-nissei-meet-challenges-of-recycled-resins-bioplastics

10. Extruder manufacturer Entek in Lebanon, Ore., found itself between massive wildfires to its north and south, but managed to maintain production with little interruption. https://www.plasticsmachinerymagazine.com/home/article/21154128/entek-keeps-production-up-despite-oregon-fires