Suppliers of new and updated hot-runner systems at K 2019 touted their innovations’ flexibility, user-friendliness and ability to contribute to the stable processing of injection molded parts.

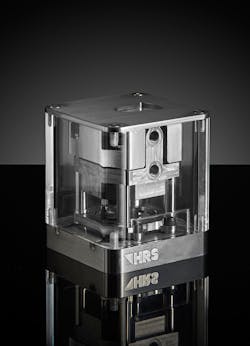

HRSflow

HRSflow updated its FLEXflow software, improved its HRScool cooling system through magnetic thermal transfer and launched new pneumatic cylinders for non-FLEXflow hot runners.

The company’s new software for its FLEXflow control unit allows users to convert data of any filling simulation performed by HRSflow into data that can be preset automatically in the control unit and in the injection molding machine. This makes it easier to match conditions with the settings of the simulation software, minimizing set-up times.

The innovation was developed to allow the direct upload of the information from the simulation software to the controller through a memory stick. All the nozzle opening and closing data sequenced during the injection phase is available, so operators have access to information about all needed settings. The software detects and automatically sets the total number of nozzles, including open- and close-trigger types, the opening/closing profiles, and any warning alarms, the company said.

The new software can be implemented in all existing FLEXflow control units using hardware versions released in or after 2017. Software updates can be done remotely. Existing recipes will be automatically translated and compatible with previous software versions, the company said.

HRSflow improved its HRScool system for hot-runner injection molding by eliminating water cooling for most common automotive parts. The system does this by minimizing heat transfer from the hot tool plate to the cylinder, while a thermally conductive cover maximizes heat dissipation from the cylinder to the cold clamping plate, the company said.

“It cools without water by transferring heat,” Chronowski said. “It has a magnetic thermal transfer that eliminates the need for cooling lines in most situations. It transfers heat away from the manifold cylinder to the plate away from the manifold by magnetic properties.”

HRSflow introduced new, compact pneumatic cylinders for non-FLEXflow hot runners. The company designed them for easy maintenance and compactness and to reduce cutouts in the mold, Chronowski said.

“The new pneumatic cylinders can be easily installed without removing the hot runner from the mold plate,” he said. They were designed for excellent thermal insulation and don’t require cooling for a wide range of polymers. No active cooling is required for manifold temperatures up to 608 degrees Fahrenheit and tool temperatures up to 248 degrees Fahrenheit.

The pneumatic cylinders can be oriented on the manifold in a variety of positions, making it possible to accommodate different hot-runner designs.

The pneumatic cylinders are available with or without an end stroke, as a damped version and with a pressure sensor.

Hasco

Hasco featured a new hot-runner system and a new range of hot-runner nozzles at K 2019. Hasco said the H4070 is the company’s first compact hot-runner system that is additively manufactured. It was designed for processing polyolefins and styrenic polymers in molds with very low shot weights and tight spacing.

Additive manufacturing provides mold makers with advantages over traditional tool making techniques. For instance, hot runners produced by the process can have tighter cavity spacing and more variable nozzle layouts, the company said. Those are key elements that contribute to the small space needed for Hasco’s new system.

“3-D printing a hot runner achieves flexibility of design,” said Neville Junkin, technical engineer for hot runners at Hasco. “This flexibility is especially useful for designing the flow channels. We can make any type of flow channel that is needed and space the channels for optimal performance. We can make channels with rounded corners instead of the typical 90-degree angles, which will minimize shearing.”

The compact system, which has 20mm TechniShot nozzles, features variable spacing between the nozzles with a minimum distance of 18mm. It also has balanced manifold blocks that are heated on both sides, he said. It is supplied fully assembled and ready to install, and is guaranteed not to leak during operation.

Due to the precision of 3-D printing, additively manufactured hot-runner systems can fill the mold at the same rate with the same amount of resin consistently, Junkin said.

“This is very important for hot-runner systems,” he said. “If they are out of balance, there will be problems when the parts come out of the mold. The parts could be warped or over-packed or under-packed. Naturally balanced means we don’t have to change the gating diameter or the melt channels from one cavity to another to achieve balancing. It ensures that the flow is identical in all the channels.”

The nozzle tips and heating unit can be mounted or removed from the front, which improves accessibility for maintenance. Nozzles up to 125mm long are available.

Hasco makes the nozzle tips for the H4070 system from heat-treated alloys such as molybdenum and copper beryllium, making them suitable for applications that require a high level of strength and performance at elevated temperatures. These individually controllable nozzles and manifolds are designed to provide uniform temperature for the reliable processing of polyolefins, styrenic polymers, and other engineered plastics with more challenging processing characteristics, the company said.

A flexible tubular heater that is easy to replace follows the melt flow closely to provide uniform heating of the manifold, the company said.

The compact hot-runner system can be used for single-cavity and multicavity molds. It is provided with a sprue bushing and is integrated into the mold. The system allows for the grouping of mold cavities in clusters.

At K 2019, the company displayed four 3-D-printed hot-runner manifolds, each with 16 nozzles, combined on a bridge to connect them together to create a 64-nozzle system with external dimensions of 220mm by 220mm.

In addition, Hasco extended its hot-runner nozzle range with the H63 Single Shot nozzle series. It is designed to offer the best price-to-performance ratio for easy-to-process plastics, the company said. It also can be used with engineering resins with a low level of reinforcement.

The company’s development focus was on compatible installation dimensions, optimum temperature control, functionality and a cost-optimized design. Different nozzle variations allow a straight feed into a sub-runner and direct gating to the molded part.

The nozzles are available in two diameters, 32mm and 40mm, with melt-channel diameters of 7mm and 9mm, respectively. The nozzles are designed to produce small and medium-sized parts with a shot weight of up to 800 grams and immersion depths up to 179mm.

Interchangeable wear parts, including tips, melt chambers and thermocouples, are designed to facilitate service and maintenance. The heating unit, located in the body of the nozzle, has only one control circuit to ensure a uniform temperature over the length of the nozzle and to allow it to fit in small spaces.

Mastip

Mastip introduced an expanded range of nozzles, a new valve gate and new valve tips.

Mastip is offering new sizes of its SX and BX nozzles and TX nozzle with FlowLoc technology. “The number of new nozzle sizes now available has doubled,” said Brett Reynolds, senior VP of international sales for Mastip.

The SX nozzle is a single nozzle. It uses two independently controlled heater zones to achieve uniform temperature distribution along its length. It’s available in H13 and 420 steel and can process temperature-sensitive resins. The SX 13 series is available in lengths ranging from 45mm to 225mm; the 16 series ranges from 45mm to 250mm; the 19 series ranges from 45mm to 300mm; and the 27 series ranges from 75mm to 450mm.

The BX nozzle is a general-purpose nozzle for low- and medium-cavitation molds that do not require hot-half construction. It is suitable for a wide range of resins and is available in H13 or 420 steel. It is offered in the same sizes as the SX nozzle.

The TX nozzle features the company’s FlowLoc technology, which consists of a threaded base that attaches to the manifold and provides secure, leak-proof operation for multicavity manifold systems, the company said. It uses embedded heaters to provide good thermal performance over a wide range of applications. It can be used for small to medium-sized automotive parts, medium to large appliance parts, large packaging and large electrical parts. It is available in 420 steel. Its 16 series ranges in length from 75mm to 250mm; its 19 series ranges from 75mm to 300mm; and its 27 series ranges from 75mm to 450mm.

The company has updated its pre-wired, pre-assembled Nexus hot-runner system with a new valve gate with pneumatic valve actuation. It is a thermally stabilized system that uses the company’s FlowLoc technology. It is designed for easy, out-of-the-box installation without additional assembly.

The hot-runner system also offers a customizable frame to match specific mold configurations and can be removed quickly from the mold, the company said. It offers a range of tip and nut options, and a variety of nozzle lengths to accommodate a wide range of applications. It is available in three series, designated as 16, 19 and 27, with nozzle lengths ranging from 75mm to 450mm. Additional nozzle lengths are available upon request, the company said.

The system features a Cylix cylinder that is mounted directly on the manifold. The valve-pin height is adjustable.

In addition, Mastip extended and redesigned its Open Valve Tip range to accommodate insulator caps. The caps are designed to provide precise valve-pin guidance and reduce wear at the gate. The redesign allows the cap insulators to clip onto the open valve tips in the G1 and G5 tip grades. The open valve tips have a groove at the end of the tip to retain the cap.

Insulation caps isolate the gate tip from polymers that require short residence times, such as PC. Cap insulators also are ideal for parts that require frequent color changes, the company said.

To extend the service life of the gate, the company also developed a new line of guided valve tips, the GVG5 line, for precise valve-pin alignment. The GVG5 tip is pre-assembled and has an open nut to improve cylindrical gate shutoff. The GVG5 also can accommodate a hard-wearing valve bushing nut with a cylindrical gate shutoff.

SISE Plastics Control Systems

SISE, a manufacturer of valve-gate controls, mold-temperature controllers and process-monitoring equipment, updated its MV3 multi-zone controller for hot-runner systems and introduced its Smart Mold Box mold-monitoring device.

The MV3 is available in six sizes and can control between eight and 336 zones, depending on the power card in use. It is available with a 7-inch, 10-inch or 12-inch color touch screen.

The MV3 uses a redesigned version of Permanent Self Tuning software that was conceived and developed by SISE. It can perform real-time mold surveillance for deviations in electrical data.

“The software continuously recalculates control parameters for each zone, immediately taking into account evolutions in the process,” said Sean Cassidy, North American operations manager at SISE. “New soft-start modes, as well as commands for raising and dropping temperature, offer comfort and security for the operator.”

The company also added scheduling capabilities to the MV3.

“The operator can set a date/time to preheat the mold before production begins, improving plant efficiency,” Cassidy said. “The plant manager can program the controller to shut off at the end of the work week to reduce energy consumption. Additionally, we can now automatically shut off the controller or force the machine to stop at a given temperature.”

The MV3 targets the packaging, automotive and medical industries.

The SISE Smart Mold Box is a stand-alone, heavy-duty device that will be available in the first quarter of this year, Cassidy said. It can be mounted on the mold and connected to cavity sensors to read temperature and/or pressure data. The box’s processors monitor molding conditions in real time to predict part quality and allow for part traceability.

“We could also pull the mold-closing sensor signal, which would allow us to count cycles,” Cassidy said. “Based on this data, and using our PC software, the user can set key indicators, reference curves and tolerances to improve part quality. We can also command switchover based on the readings.”

The Smart Mold Box is designed to track the mold throughout its life cycle, both during production and while it’s in storage.

Bruce Adams, senior staff reporter

Contact

Hasco America Inc., Fletcher, N.C., 828-650-2600, www.hasco.com

HRSflow, Byron Center, Mich., 616-228-6900, www.hrsflow.com

Mastip, Slinger, Wis., 262-644-9400, www.mastip.com

SISE Plastics Control Systems Inc., Atlanta, 404-495-5968, http://en.sise-plastics.com