DVT extrusion technology improves degassing

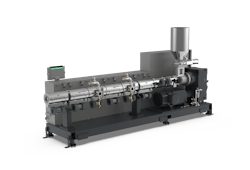

BC 120-40 DVT This new single-screw extruder from Battenfeld-Cincinnati is the first to demonstrate the company’s latest degassing strategies. Called the Dual Vent Technology (DVT), the new technology involves two zones: Volatile substances with low partial pressure are removed from the melt in the first zone, while volatile substances with higher partial pressure are removed in the second. While Battenfeld Cincinnati developed the extruder with a focus on ABS processing, the extruder also is appropriate for regrinds, as well as materials with untreated residues and regrinds.

What’s new? The extruder’s Dual Vent Technology (DVT). While other single-screw extruders also employ double degassing, the BC 120-40 DVT takes a new approach. In other extruders, degassing connections are located next to each other and serve to increase overall degassing in a single area. But Battenfeld-Cincinnati's new DVT creates two independent degassing areas along the extruder's processing unit.

Benefits Improved removal of gases, volatiles and moisture, and greater flexibility, when compared with other single-screw extruders. The extruder efficiently processes raw materials and produces high-quality films and sheets, with almost no material pretreatment. It gives processors another option in handling difficult-to-process materials, and, with the DVT, might also be appropriate for odor removal.

Battenfeld-Cincinnati, McPherson, Kan., 620-241-6843, www.battenfeld-cincinnati.com