By Ron Shinn

Reifenhäuser has developed a Carbon Footprint Dashboard that lets producers of film and nonwovens see changes in their manufacturing process and helps identify how they can reduce emissions. It is believed to be the first easy-to-use carbon calculator device for processors.

Tim Pohl, director of sustainability and business development at the Reifenhäuser Group in Troisdorf, Germany, said carbon footprint can be difficult to calculate.

“The Carbon Footprint Dashboard shows the different emission sources over the production period,” Pohl said. “In the basic version, assumptions are made about the carbon footprint of the raw materials used, and the calculation is based on the energy mix of Europe, for example. This is sufficient to determine the initial potential for carbon footprint reduction.”

Reifenhäuser can customize for local conditions to provide a more precise calculation, he said.

Pohl said the calculation can become even more important when in-house recycled material is processed.

Why is a processor’s carbon footprint important?

Other than the obvious environmental benefits of reducing harmful emissions, Pohl said that a CO2 savings is generally accompanied by savings in energy and raw materials.

He also said that processors can show their carbon footprint data to third parties to certify a particular product line as sustainable. This can lead to new sales opportunities.

The dashboard runs on Reifenhäuser’s digital solution ExtrusionOS and c.Hub middleware.

Reifenhäuser has been working to lower its own corporate carbon footprint for more than 10 years.

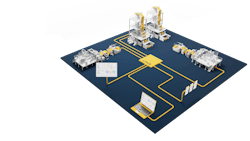

The c.Hub, a middleware product that facilitates the secure exchange of data between different IT systems, applications, extrusion machines and line controls, is at the heart of a new Reifenhäuser initiative to get processors to fully exploit the potential of digitalization.

Launched at K 2022, the digital offensive is aimed at getting all processors to start using available digital tools. It said it is offering easy-to-implement, open digital solutions designed to help producers increase their efficiency. Reifenhäuser said all customers, regardless of size, can benefit from the program.

The c.Hub is the single point for collecting and digesting all relevant production data. Users can access all data from anywhere. Data is collected and stored without interfering with the production process.

“So far, digitization in our industry has mostly failed due to heterogeneous factories with machines and peripherals from different vendors and of different ages and types, as well as applications that are not connected with each other,” said Daniel Kajan, director of product and operations at RE:, a Reifenhäuser Group subsidiary that specializes in digital products for extrusion lines.

“Without looking at the big picture, however, production is inefficient and error-prone. Unnecessary complaints, material loss and downtime are the result,” Kajan said in a press release. “Only a cross-vendor solution maps the production reality.”

The c.Hub has out-of-the-box connections for most industrial protocols. The associated ExtrusionOS software provides user-friendly applications and dashboards to monitor, manage, store and analyze data.

The new digital package can be purchased with Reifenhäuser machines or retrofitted on existing lines and servers.

Ron Shinn, editor

Contact:

Reifenhäuser Inc., Maize, Kan., 316-260-2122, www.reifenhauser.com

About the Author

Ron Shinn

Editor

Editor Ron Shinn is a co-founder of Plastics Machinery & Manufacturing and has been covering the plastics industry for more than 35 years. He leads the editorial team, directs coverage and sets the editorial calendar. He also writes features, including the Talking Points column and On the Factory Floor, and covers recycling and sustainability for PMM and Plastics Recycling.