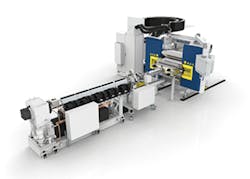

Reifenhäuser Cast Sheet Coating, Troisdorf, Germany, has introduced a new coextrusion feedblock and additional sizes of polishing roll stacks for sheet production.

The company's REIcofeed coextrusion feedblock, designed for the production of film or sheet with 11 or more layers, gains a new model that allows for encapsulation of a multilayer film inside of the feedblock. This feature, incorporated into the REIcofeed 2.2 model, eliminates the need for an encapsulation device in the flat die, and the use of an additional extruder. The design of the REIcofeed 2.2 allows for optimal adjustment of the layers during production.

Reifenhäuser also announced it is extending its Mirex-MT line of polishing stacks. The Mirex-MT polishing stacks feature a mechatronic nip-adjusting system and are designed to be an integral part of a Reifenhäuser production line incorporating a high-performance sheet extruder. The polishing stacks calibrate and cool the rigid sheet, creating a smooth surface.

Reifenhäuser says the new Mirex-MT-Hi, an inline horizontal, extrusion-direction polishing stack, is the smallest in the Mirex line, and is only used in the production of PS and PP sheet. It handles sheet in thicknesses from 0.3mm to 2mm. Mirex-MT-Hi has three 12-inch diameter polishing rolls, which can accommodate sheet widths from approximately 22 to 34 inches. The highly efficient machine has a small footprint.

Mirex-MT polishing stacks also can be configured with rolls that are 16 inches or 27.5 inches in diameter. The available sizes correspond to common thermoformer sizes. The size of the polishing roll selected depends on the output of the extruded sheet line. Reifenhäuser will officially introduce a complete production line that incorporates the Mirex-MT-Hi polishing stack at the K show.

The polishing stack can also be used offline, without connecting to a thermoforming machine. It can be purchased separately as a retrofit for existing lines, including for use with non-Reifenhäuser equipment.

Reifenhäuser also offers the Mirex-MT-V-AX high-performance series polishing stack and the Mirex-MT-H for PS and PP sheet, which processes 200 pounds per hour of material into sheet with widths from 27.5 inches to 57 inches.

The company has a U.S. subsidiary, Reifenhauser Inc., in Maize, Kan.

EXTRUSION LINE FOR RIGID PP SHEET IS COMPACT

Sunwell Machines Co. Ltd., Changhua, Taiwan, is offering a new compact and energy-saving extruder for the production of PP sheet. The company is represented in the U.S. by Sunwell USA LLC.

The new HSE75 extruder features a 75mm-diameter screw with a 36:1 L:D ratio, and can produce PP sheet in thicknesses ranging from 300 microns to 2mm. The unit has a maximum line speed of about 200 feet per minute. The company said that its small footprint, low energy consumption and economical price will help it compete with conventional extruders.

Mikell Knights, senior correspondent

Contact:

Reifenhauser Inc., 316-260-2122, www.reifenhauserinc.com

Sunwell USA LLC, 509-454-4578, www.tslusa.biz, www.sunwellglobal.com.tw