D-S direct drive allows 30 percent energy savings

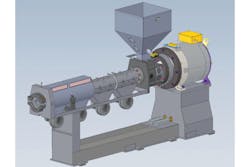

DIRECT DRIVE EXTRUDER Davis-Standard is highlighting its direct drive extruder technology. Direct drive technology is the alternative to AC and DC extruder models. The D-S line of Ecotruders particularly is geared toward the "greening" of the extrusion industry.

WHAT'S NEW? The technology constantly is evolving; D-S is continually developing innovative control algorithms, such as patented adaptive dual thermocouple technology, to maintain tight control of process temperatures. Recent developments in this area led to work on how to minimize the convective heat losses in the extruder's air cooling system. There also is a patent-pending development of an active air damper system to effectively minimize the convective heat losses experienced on current designs.

BENEFITS Overall greater energy savings; the direct drive motor compared to a conventional AC motor gearbox allows for 10 to 15 percent energy savings; the optimized screw design yielded energy savings of up to 18 percent; and the new heating/cooling system design allows for energy savings of between 14 percent and 18 percent.

Davis-Standard LLC, Pawcatuck, R.I., 860-599-1010, www.davis-standard.com