Patent Report: Microwave heating of preforms

Preform heating. A new way to heat injection molded bottle preforms with microwaves is the subject of a patent application from Krones AG, Neutraubling, Germany.

According to the application, the prior art for heating preforms before blow molding or stretch blow molding has typically relied on infrared ovens. The more recent introduction of microwave ovens has been successful but introduces a level of complexity in both design and production.

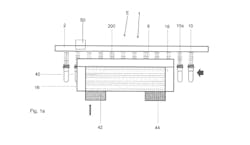

The application describes a transport device that conveys preforms along a path, including through a stationary heating portion. In the heating portion there is an applicator device that bombards the preforms with microwaves to heat them. In a preferred embodiment, the applicator device has a narrow slot that can accommodate preforms as they travel along the path.

The patent application includes the possibility of rotating the preforms along their longitudinal axis as they pass through the application device to ensure that they are uniformly heated.

Holding devices, preferably utilizing an internal gripper device, secure the preforms as they are transported through the applicator device, and in some embodiments both the holding devices and the mouths of the preforms remain outside the applicator device to avoid excessive heating.

By keeping the transport device outside of the applicator device, damage to transport device components can be avoided. This also prevents the escape of microwave radiation that could occur if conductive metallic elements entered the applicator device.

Other embodiments described in the patent application propose making the holding devices at least in part from dielectric material to insulate against electrical conductivity, or making them, at least partially, of materials that cannot be heated by microwaves.

The patent application also envisions the use of multiple stages of shielding to reduce the escape of microwaves from the applicator device. To improve safety, the application suggests employing one microwave leakage detection measuring device inside the protective housing of the system, and another outside the housing. If levels exceed safety limits, the microwave power can be switched off automatically.

In another embodiment, the apparatus can employ multiple sensors to monitor the temperature of the preforms as they travel through the heating portion, and “In a particularly preferred embodiment, the apparatus comprises a control device which allows control and in particular regulation of the heating device, and in particular real-time regulation,” the patent application states.

Patent application 20210046677, published February 18