Patent Report: Krones improves preform heating

Preform heating. An apparatus and method to quickly and reliably heat preforms to a target temperature are the subject of a patent application from Krones AG, Neutraubling, Germany. Current technologies frequently feature a transport device that carries preforms through a heating section using infrared heating elements or microwaves, according to the patent application. After the preforms leave the heating section, a device, such as a pyrometer, measures the preforms’ temperature. This measurement is used to adjust the heating power so that preforms are exiting the heating area at a temperature that is stable for the blow molding process.

However, variables such as inconsistent preform storage temperatures or lack of uniform temperature control within a building mean preforms can enter the heating section at unexpected temperatures. It takes about 20 seconds from the time preforms enter the heating section until they exit and have their temperature measured. That time lag, plus the additional time it may take to adjust the heating section’s temperature, means many preforms or the containers they become may need to be discarded, especially early in a production run.

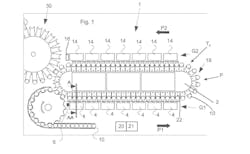

The invention offers faster temperature adjustments and shorter downtimes. It employs two heating sections that are arrayed along the straight portion of an oval-shaped section of the transport device. As the preforms move along the transport device, an instrument measures their temperature just prior to their entering the first heating section. These measurements are transferred to a control device, which “can then preferably determine a difference between the actual temperature of the plastic preforms and the assumed temperature … and in this way can then calculate the energy which is required in order to bring the plastic preforms to a defined starting level,” the application states.

In some embodiments of the invention, the heating section has a series of heating elements that can be controlled individually. The preforms then move through a second heating section, also with individually controlled heating elements. The preforms pass another instrument that confirms the preforms are at a target temperature, or if not, that information is used to adjust temperatures in the second heating section.

Patent application 20200307064, published Oct. 1